Каталог Iscar инструментальная оснастка 2022 - страница 119

Навигация

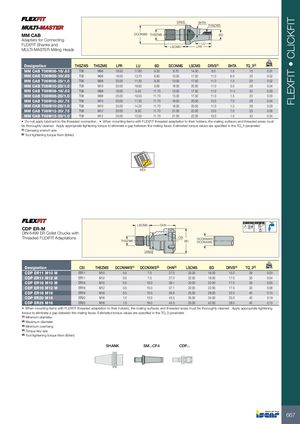

FLEXFIT • CLICKFIT DRVS BHTA THSZWS MM CAB DCONMS THSZMS BD Adapters for Connecting FLEXFIT Shanks and LULSCMSLPR MULTI-MASTER Milling Heads Designation THSZWS THSZMS LPR LU BD DCONMS LSCMS DRVS(1) BHTA TQ_3(2) kg MM CAB T06M06-16/.63 T06 M06 16.00 11.60 9.30 9.70 14.50 8.0 1.5 15 0.01 MM CAB T06M08-16/.63 T06 M08 16.00 13.70 9.60 13.00 17.50 11.0 6.0 20 0.02 MM CAB T06M08-25/1.0 T06 M08 25.00 11.30 9.30 13.00 17.50 11.0 1.5 20 0.02 MM CAB T06M10-25/1.0 T06 M10 25.00 16.60 9.60 18.00 20.00 11.0 5.0 29 0.04 MM CAB T08M08-16/.63 T08 M08 16.00 5.40 11.70 13.00 17.50 11.0 11.4 20 0.03 MM CAB T08M08-25/1.0 T08 M08 25.00 19.50 11.70 13.00 17.50 11.0 1.5 20 0.03 MM CAB T08M10-20/.75 T08 M10 20.00 11.30 11.70 18.00 20.00 13.0 7.0 29 0.04 MM CAB T08M10-25/1.0 T08 M10 25.00 14.20 11.70 18.00 20.00 11.0 1.5 29 0.03 MM CAB T08M12-20/.75 T08 M12 20.00 9.30 11.70 21.00 22.00 13.0 7.0 33 0.05 MM CAB T08M12-25/1.0 T08 M12 25.00 12.50 11.70 21.00 22.00 13.0 1.5 33 0.04 • Do not apply lubricant to the threaded connection • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter (1) Clamping wrench size (2) Tool tightening torque Nxm (lbfxin) 664 A 0.003 A 58-60 HRc LSCMS OHN CDP ER-M DIN 6499 ER Collet Chucks with Threaded FLEXFIT Adaptations THSZMS CSI BD DCONNWSDCONXWS DRVS Designation CSI THSZMS DCONNWS(1) DCONXWS(2) OHN(3) LSCMS BD DRVS(4) TQ_3(5) kg CDP ER11 M10 M ER11 M10 0.5 7.0 27.0 20.00 16.00 15.0 29 0.03 CDP ER11 M12 M ER11 M12 0.5 7.0 27.0 22.00 16.00 17.0 33 0.04 CDP ER16 M10 M ER16 M10 0.5 10.0 38.1 20.00 22.00 17.0 29 0.05 CDP ER16 M12 M ER16 M12 0.5 10.0 37.1 22.00 22.00 17.0 33 0.06 CDP ER16 M16 ER16 M16 0.5 10.0 36.6 25.00 28.00 25.0 40 0.10 CDP ER20 M16 ER20 M16 1.0 13.0 45.5 25.00 34.00 25.0 40 0.19 CDP ER25 M16 ER25 M16 1.0 16.0 44.5 25.00 42.00 28.0 40 0.15 • When mounting items with FLEXFIT threaded adaptation to their holders, the mating surfaces and threaded areas must be thoroughly cleaned. Apply appropriate tightening torque to eliminate a gap between the mating faces. Estimated torque values are specified in the TQ_3 parameter (1) Minimum diameter (2) Maximum diameter (3) Minimum overhang (4) Torque key size (5) Tool tightening torque Nxm (lbfxin) SHANK SM...CF4 CDP... 667

Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar обработка канавок 2022

Каталог Iscar обработка канавок 2022 Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018