Каталог Iscar инструмент для внутренней обработки - страница 129

Навигация

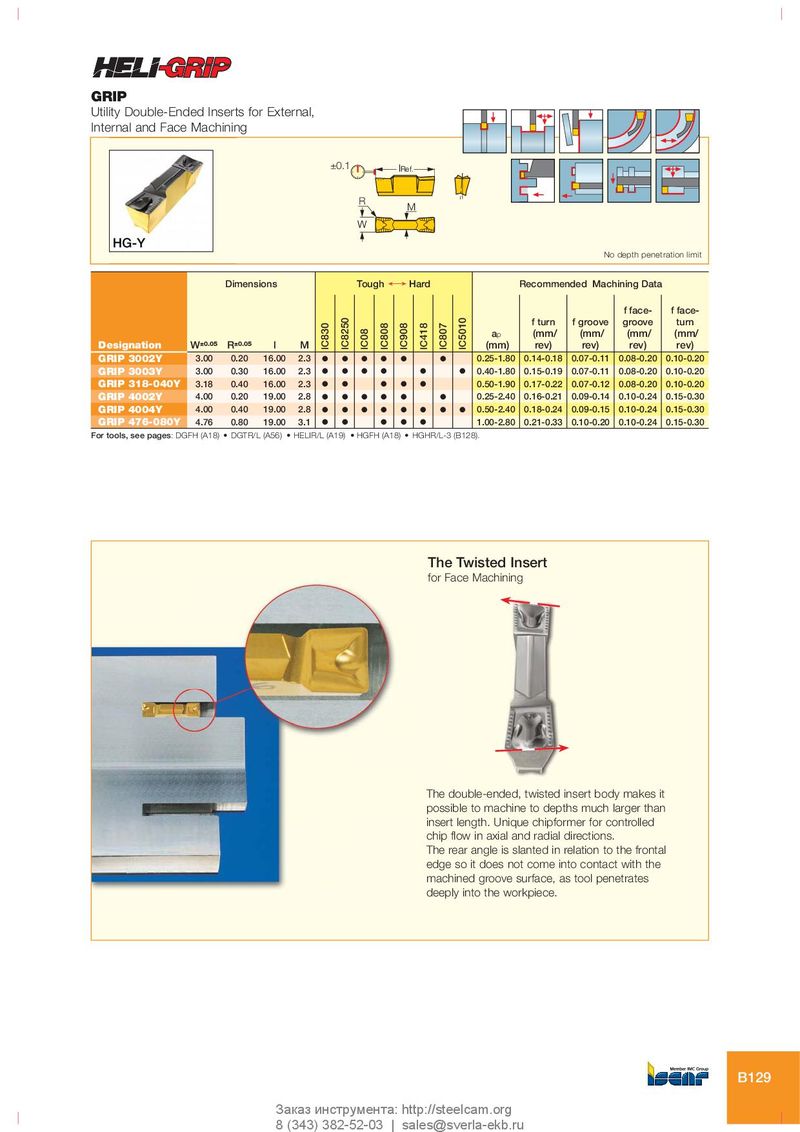

GRIP Utility Double-Ended Inserts for External, Internal and Face Machining ±0.1 lRef. R M W No depth penetration limit Dimensions Tough ¥ Hard Recommended Machining Data f face- f face- f turn f groove groove turn a p (mm/ (mm/ (mm/ (mm/ Designation W ±0.05 R ±0.05 l M IC830 IC8250 IC08 IC808 IC908 IC418 IC807 IC5010 (mm) rev) rev) rev) rev) GRIP 3002Y 3.00 0.20 16.00 2.3 O O O O O O 0.25-1.80 0.14-0.18 0.07-0.11 0.08-0.20 0.10-0.20 GRIP 3003Y 3.00 0.30 16.00 2.3 O O O O O O 0.40-1.80 0.15-0.19 0.07-0.11 0.08-0.20 0.10-0.20 GRIP 318-040Y 3.18 0.40 16.00 2.3 O O O O O 0.50-1.90 0.17-0.22 0.07-0.12 0.08-0.20 0.10-0.20 GRIP 4002Y 4.00 0.20 19.00 2.8 O O O O O O 0.25-2.40 0.16-0.21 0.09-0.14 0.10-0.24 0.15-0.30 GRIP 4004Y 4.00 0.40 19.00 2.8 O O O O O O O O 0.50-2.40 0.18-0.24 0.09-0.15 0.10-0.24 0.15-0.30 GRIP 476-080Y 4.76 0.80 19.00 3.1 O O O O O 1.00-2.80 0.21-0.33 0.10-0.20 0.10-0.24 0.15-0.30 For tools, see pages: DGFH (A18) • DGTR/L (A56) • HELIR/L (A19) • HGFH (A18) • HGHR/L-3 (B128). The Twisted Insert for Face Machining The double-ended, twisted insert body makes it possible to machine to depths much larger than insert length. Unique chipformer for controlled chip flow in axial and radial directions. The rear angle is slanted in relation to the frontal edge so it does not come into contact with the machined groove surface, as tool penetrates deeply into the workpiece. B129 Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru

Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar обработка канавок 2022

Каталог Iscar обработка канавок 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar инструмент для мелкоразмерной обработки

Каталог Iscar инструмент для мелкоразмерной обработки Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022