Каталог Iscar инструмент для мелкоразмерной обработки - страница 52

Навигация

Каталог Iscar дисковые фрезы и фрезерные пластины 2022

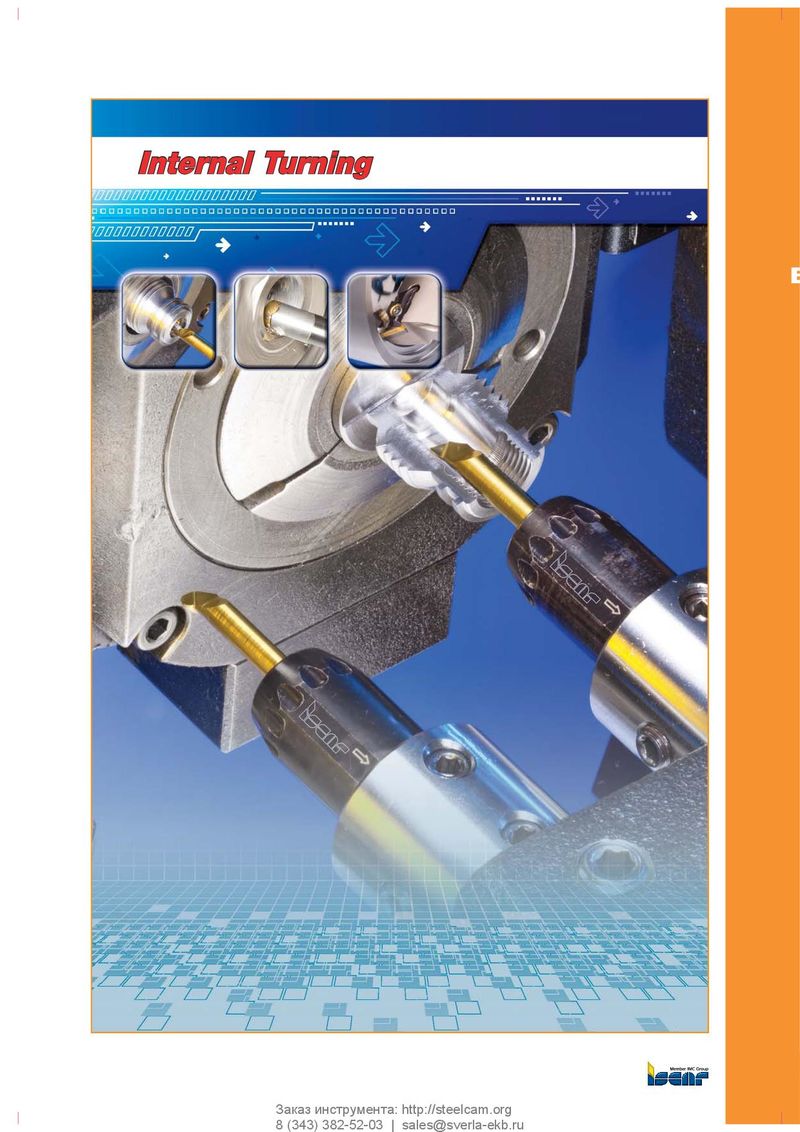

Каталог Iscar дисковые фрезы и фрезерные пластины 2022 Каталог Iscar инструмент для внутренней обработки

Каталог Iscar инструмент для внутренней обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018

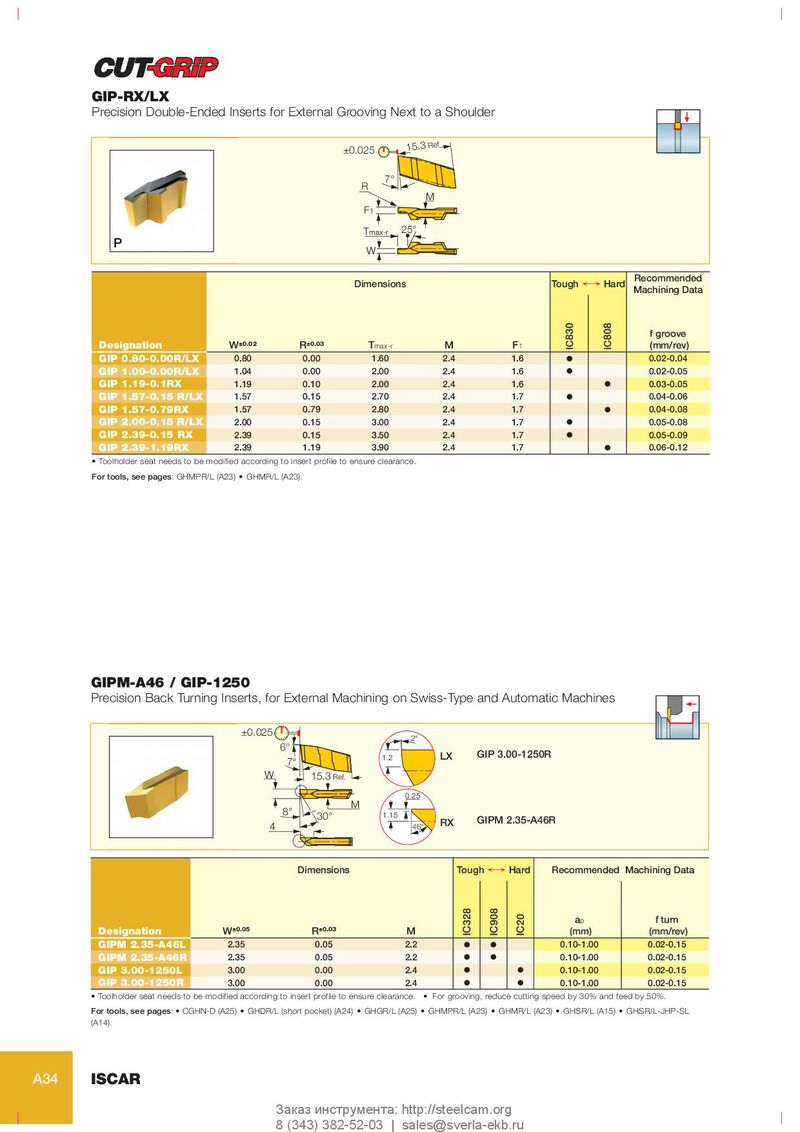

GIP-RX/LX Precision Double-Ended Inserts for External Grooving Next to a Shoulder ±0.025 15.3 Ref 7° R M F1 Tmax-r 25° W Recommended Dimensions Tough ¥ Hard Machining Data f groove Designation W ±0.02 R ±0.03 T max-r M F 1 IC830 IC808 (mm/rev) GIP 0.80-0.00R/LX 0.80 0.00 1.60 2.4 1.6 O 0.02-0.04 GIP 1.00-0.00R/LX 1.04 0.00 2.00 2.4 1.6 O 0.02-0.05 GIP 1.19-0.1RX 1.19 0.10 2.00 2.4 1.6 O 0.03-0.05 GIP 1.57-0.15 R/LX 1.57 0.15 2.70 2.4 1.7 O 0.04-0.06 GIP 1.57-0.79RX 1.57 0.79 2.80 2.4 1.7 O 0.04-0.08 GIP 2.00-0.15 R/LX 2.00 0.15 3.00 2.4 1.7 O 0.05-0.08 GIP 2.39-0.15 RX 2.39 0.15 3.50 2.4 1.7 O 0.05-0.09 GIP 2.39-1.19RX 2.39 1.19 3.90 2.4 1.7 O 0.06-0.12 • Toolholder seat needs to be modified according to insert profile to ensure clearance. For tools, see pages: GHMPR/L (A23) • GHMR/L (A23). GIPM-A46 / GIP-1250 Precision Back Turning Inserts, for External Machining on Swiss-Type and Automatic Machines ±0.025 2° 6° 1.2 LX GIP 3.00-1250R 7° W 15.3 Ref. 0.25 M 8° 30° 1.15 46° RX GIPM 2.35-A46R 4 Dimensions Tough ¥ Hard Recommended Machining Data a p f turn Designation W ±0.05 R ±0.03 M IC328 IC908 IC20 (mm) (mm/rev) GIPM 2.35-A46L 2.35 0.05 2.2 O O 0.10-1.00 0.02-0.15 GIPM 2.35-A46R 2.35 0.05 2.2 O O 0.10-1.00 0.02-0.15 GIP 3.00-1250L 3.00 0.00 2.4 O O 0.10-1.00 0.02-0.15 GIP 3.00-1250R 3.00 0.00 2.4 O O 0.10-1.00 0.02-0.15 • Toolholder seat needs to be modified according to insert profile to ensure clearance. • For grooving, reduce cutting speed by 30% and feed by 50%. For tools, see pages: • CGHN-D (A25) • GHDR/L (short pocket) (A24) • GHGR/L (A25) • GHMPR/L (A23) • GHMR/L (A23) • GHSR/L (A15) • GHSR/L-JHP-SL (A14). A34 ISCAR Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru