Общий каталог Ingersoll 2016 - 2017 - страница 46

Навигация

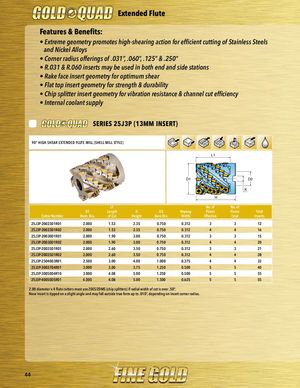

Extended Flute Features & Benefits: • Extreme geometry promotes high-shearing action for efficient cutting of Stainless Steels and Nickel Alloys • Corner radius offerings of .031”, .060”, .125” & .250” • R.031 & R.060 inserts may be used in both end and side stations • Rake face insert geometry for optimum shear • Flat top insert geometry for strength & durability • Chip splitter insert geometry for vibration resistance & channel cut efficiency • Internal coolant supply SERIES 25J3P (13MM INSERT) 90° HIGH SHEAR EXTENDED FLUTE MILL (SHELL MILL STYLE) L1 D1 D2 K H L1 No. of No. of D1 Length H D2 Keyway Flutes Flutes Total Cutter Number Nom. Dia. of Cut Height Bore Dia. Width Effective Total Inserts 25J3P-20023D1R01 2.000 1.53 2.35 0.750 0.312 3 3 12 25J3P-20023D1R02 2.000 1.53 2.35 0.750 0.312 4 4 16 25J3P-20030D1R01 2.000 1.90 3.00 0.750 0.312 3 3 15 25J3P-20030D1R02 2.000 1.90 3.00 0.750 0.312 4 4 20 25J3P-20035D1R01 2.000 2.60 3.50 0.750 0.312 3 3 21 25J3P-20035D1R02 2.000 2.60 3.50 0.750 0.312 4 4 28 25J3P-25040D3R01 2.500 3.00 4.00 1.000 0.375 4 4 32 25J3P-30037D4R01 3.000 3.00 3.75 1.250 0.500 5 5 40 25J3P-30050D4R10 3.000 4.08 5.00 1.250 0.500 5 5 55 25J3P-40050D5R01 4.000 4.08 5.00 1.500 0.625 5 5 55 2.00 diameter x 4 flute cutters must use ZDES/ZDMS (chip splitters) if radial width of cut is over .50“. Nose insert is tipped on a slight angle and may fall outside true form up to .010“, depending on insert corner radius. 44

Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021 Общий каталог Ingersoll 2011

Общий каталог Ingersoll 2011 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014