Общий каталог Ingersoll 2013 - 2014 - страница 34

Навигация

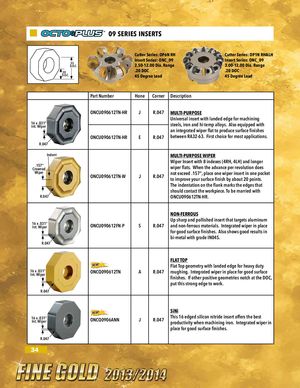

09 SERIES INSERTS Cutter Series: OP6N RH Cutter Series: OP1N RH&LH Insert Series: ONC_09 Insert Series: ONC_09 .55D.O.C. 2.50-12.00 Dia. Range 3.00-12.00 Dia. Range .20 .20 DOC .20 DOC D.O.C. 45 Degree Lead 45 Degree Lead Part Number Hone Corner Description ONCU090612TN-HR J R.047 MULTI-PURPOSE Universal insert with landed edge for machining 16 x .031”Int. Wiper steels, iron and hi-temp alloys. Also equipped with an integrated wiper flat to produce surface finishes ONCU090612TN-HR E R.047 between RA32-63. First choice for most applications. R.047 Indent MULTI-PURPOSE WIPER Wiper Insert with 8 indexes (4RH, 4LH) and longer .157”Crowned wiper flats. When the advance per revolution does Wiper ONCU090612TN-W J R.047 not exceed .157", place one wiper insert in one pocketto improve your surface finish by about 20 points. The indentation on the flank marks the edges that should contact the workpiece. To be married with R.047 ONCU090612TN-HR. NON-FERROUS Up sharp and pollished insert that targets aluminum 16 x .031”Int. Wiper ONCU090612FN-P S R.047 and non-ferrous materials. Integrated wiper in place for good surface finishes. Also shows good results in bi-metal with grade IN04S. R.047 FLAT TOP Flat Top geometry with landed edge for heavy duty 16 x .031”Int. Wiper ONCQ090612TN A R.047 roughing. Integrated wiper in place for good surface finishes. If other positive geometries notch at the DOC, put this strong edge to work. R.047 SiNi 16 x .031”Int. Wiper ONCQ0906ANN J R.047 This 16 edged silicon nitride insert offers the bestproductivity when machining iron. Integrated wiper in place for good surface finishes. R.047 34

Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021 Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2011

Общий каталог Ingersoll 2011 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014