Общий каталог Ingersoll 2013 - 2014 - страница 30

Навигация

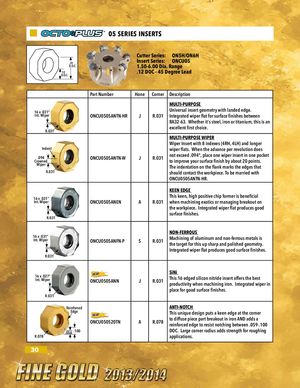

05 SERIES INSERTS Cutter Series: ON5H/ON6H .31 Insert Series: ONCU05 D.O.C. 1.50-6.00 Dia. Range .12 .12 DOC - 45 Degree Lead D.O.C. Part Number Hone Corner Description MULTI-PURPOSE 16 x .031” Universal insert geometry with landed edge. Int. Wiper ONCU0505ANTN-HR J R.031 Integrated wiper flat for surface finishes between RA32-63. Whether it's steel, iron or titanium, this is an excellent first choice. R.031 MULTI-PURPOSE WIPER Wiper Insert with 8 indexes (4RH, 4LH) and longer Indent wiper flats. When the advance per revolution does .094Crowned ONCU0505ANTN-W J R.031 not exceed .094", place one wiper insert in one pocketto improve your surface finish by about 20 points. Wiper The indentation on the flank marks the edges that R.031 should contact the workpiece. To be married with ONCU0505ANTN-HR. KEEN EDGE 16 x .031” This keen, high positive chip former is beneficial Int. Wiper ONCU0505ANEN A R.031 when machining exotics or managing breakout on the workpiece. Integrated wiper flat produces good surface finishes. R.031 NON-FERROUS 16 x .031”Int. Wiper ONCU0505ANFN-P S R.031 Machining of aluminum and non-ferrous metals isthe target for this up sharp and polished geometry. Integrated wiper flat produces good surface finishes. R.031 SiNi 16 x .027”Int. Wiper ONCU0505ANN J R.031 This 16 edged silicon nitride insert offers the bestproductivity when machining iron. Integrated wiper in place for good surface finishes. R.031 Reinforced ANTI-NOTCH Edge This unique design puts a keen edge at the corner ONCU050520TN A R.078 to diffuse piece part breakout in iron AND adds areinforced edge to resist notching between .059-.100 .056 .100 DOC. Large corner radius adds strength for roughing R.078 applications. 30

Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021 Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2011

Общий каталог Ingersoll 2011 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014