Общий каталог Ingersoll 2013 - 2014 - страница 153

Навигация

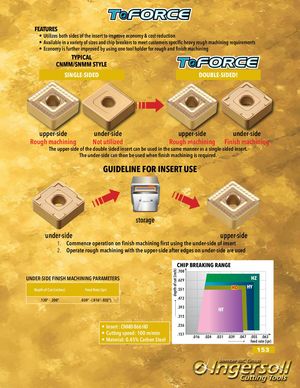

FEATURES • Utilizes both sides of the insert to improve economy & cost reduction • Available in a variety of sizes and chip breakers to meet customers specific heavy rough machining requirements • Economy is further improved by using one tool holder for rough and finish machining TYPICAL CNMM/SNMM STYLE SINGLE-SIDED DOUBLE-SIDED! upper-side under-side upper-side under-side Rough machining Not utilized Rough machining Finish machining The upper-side of the double sided insert can be used in the same manner as a single-sided insert. The under-side can then be used when finish machining is required. GUIDELINE FOR INSERT USE storage under-side upper-side 1. Commence operation on finish machining first using the under-side of insert 2. Operate rough machining with the upper-side after edges on under-side are used CHIP BREAKING RANGE .708 UNDER-SIDE FINISH MACHINING PARAMETERS .629 HZ Depth of Cut (inches) Feed Rate (ipr) .551 HD HY .120” - .200” .024” - (.016”-.032”) .472 .393 HT .315 • Insert : CNMD 866 HD .236 • Cutting speed: 100 m/min• Material: 0.45% Carbon Steel .157 .016 .024 .031 .039 .047 .055 .063feed rate (ipr) 153 depth of cut (inch)

Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021 Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2011

Общий каталог Ingersoll 2011 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014