Общий каталог Ingersoll 2013 - 2014 - страница 126

Навигация

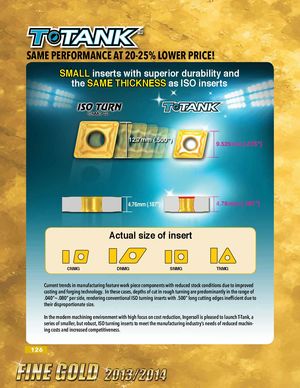

SAME PERFORMANCE AT 20-25% LOWER PRICE! SMALL inserts with superior durability and the SAME THICKNESS as ISO inserts Actual size of insert CNMG DNMG SNMG TNMG Current trends in manufacturing feature work piece components with reduced stock conditions due to improved casting and forging technology. In these cases, depths of cut in rough turning are predominantly in the range of .040”~.080” per side, rendering conventional ISO turning inserts with .500” long cutting edges inefficient due to their disproportionate size. In the modern machining environment with high focus on cost reduction, Ingersoll is pleased to launch T-Tank, a series of smaller, but robust, ISO turning inserts to meet the manufacturing industry’s needs of reduced machin- ing costs and increased competitiveness. 126

Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021 Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2011

Общий каталог Ingersoll 2011 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014