Общий каталог Ingersoll 2011 - страница 837

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

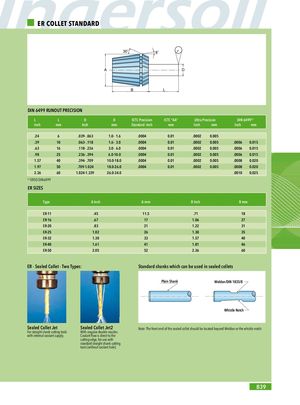

ER COLLET STANDARD 30˚ 8˚ A D B L DIN 6499 RUNOUT PRECISION L L D D ICTC Precision ICTC “AA” Ultra Precision DIN 6499(1) Inch mm Inch mm Standard -Inch mm Inch mm Inch mm .24 6 .039- .063 1.0- 1.6 .0004 0.01 .0002 0.005 .39 10 .063- .118 1.6- 3.0 .0004 0.01 .0002 0.005 .0006 0.015 .63 16 .118- .236 3.0- 6.0 .0004 0.01 .0002 0.005 .0006 0.015 .98 25 .236- .394 6.0-10.0 .0004 0.01 .0002 0.005 .0006 0.015 1.57 40 .394- .709 10.0-18.0 .0004 0.01 .0002 0.005 .0008 0.020 1.97 50 .709-1.024 18.0-26.0 .0004 0.01 .0002 0.005 .0008 0.020 2.36 60 1.024-1.339 26.0-34.0 .0010 0.025 (1) ER50 DIN6499 ER SIZES Type A Inch A mm B Inch B mm ER-11 .45 11.5 .71 18 ER-16 .67 17 1.06 27 ER-20 .83 21 1.22 31 ER-25 1.02 26 1.38 35 ER-32 1.30 33 1.57 40 ER-40 1.61 41 1.81 46 ER-50 2.05 52 2.36 60 ER - Sealed Collet - Two Types: Standard shanks which can be used in sealed collets Plain Shank Weldon/DIN 1835/B Whistle Notch Sealed Collet Jet Sealed Collet Jet2 Note: The front end of the sealed collet should be located beyond Weldon or the whistle notch. For straight shank cutting tools With angular double nozzles. with internal coolant supply. Coolant flow is direct to the cutting edge, for use with standard straight shank cutting tools (without coolant hole). 839

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021