Общий каталог Ingersoll 2011 - страница 692

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

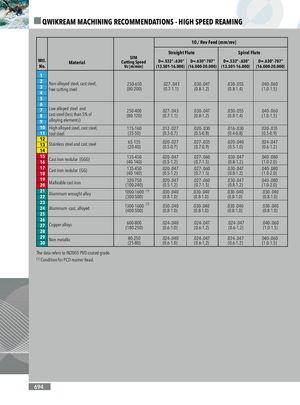

QWIKREAM MACHINING RECOMMENDATIONS - HIGH SPEED REAMING QwikReam Machining Recommendations - High Speed Reaming 10./ Rev Feed (mm/rev) Straight Flute Spiral Flute Mtl. Material SFMCutting Speed D=.532”-.630” D=.630”-787” D=.532”-.630” D=.630”-787” No. Vc (m/min) (13.501-16.000) (16.000-20.000) (13.501-16.000) (16.000-20.000) 1 2 Non-alloyed steel, cast steel,3free cutting steel250-650 .027-.043 .030-.047 .030-.055 .040-.060(80-200)(0.7-1.1)(0.8-1.2)(0.8-1.4)(1.0-1.5) 4 5 6 7 Low alloyed steel and 250-400 .027-.043 .030-.047 .030-.055 .040-.060 8 cast steel (less than 5% of (80-120) (0.7-1.1) (0.8-1.2) (0.8-1.4) (1.0-1.5) 9 alloying elements) 10 High alloyed steel, cast steel, 115-160 .012-.027 .020-.030 .016-.030 .020-.035 11 tool steel (35-50) (0.3-0.7) (0.5-0.8) (0.4-0.8) (0.5-0.9) 1213Stainless steel and cast steel 65-135 .020-.027 .027-.035 .020-.040 .024-.047(20-40)(0.5-0.7)(0.7-0.9)(0.5-1.0)(0.6-1.2) 14 1516Cast iron nodular (GGG) 135-450 .020-.047 .027-.060 .030-.047 .040-.080(40-140)(0.5-1.2)(0.7-1.5)(0.8-1.2)(1.0-2.0) 1718Cast iron nodular (GG) 135-450 .020-.047 .027-.060 .030-.047 .040-.080(40-140)(0.5-1.2)(0.7-1.5)(0.8-1.2)(1.0-2.0) 1920Malleable cast iron 320-750 .020-.047 .027-.060 .030-.047 .040-.080(100-240)(0.5-1.2)(0.7-1.5)(0.8-1.2)(1.0-2.0) 2122Aluminum wrought alloy 1000-1600 (1) .030-.040 .030-.040 .030-.040 .030-.040(300-500)(0.8-1.0)(0.8-1.0)(0.8-1.0)(0.8-1.0) 2324Aluminum -cast, alloyed 1300-1600 (1) .030-.040 .030-.040 .030-.040 .030-.040(400-500)(0.8-1.0)(0.8-1.0)(0.8-1.0)(0.8-1.0) 25 2627Copper alloys 600-800 .024-.040 .024-.047 .024-.047 .040-.060(180-250)(0.6-1.0)(0.6-1.2)(0.6-1.2)(1.0-1.5) 28 2930Non metallic 80-250 .024-.040 .024-.047 .024-.047 .040-.060(25-80)(0.6-1.0)(0.6-1.2)(0.6-1.2)(1.0-1.5) The data refers to IN2005 PVD coated grade. (1) Condition for PCD reamer head. 694

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021