Общий каталог Ingersoll 2011 - страница 668

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

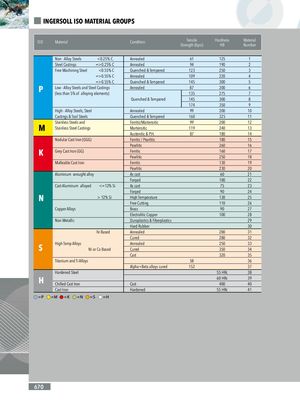

INGERSOLL ISO MATERIAL GROUPS (CONT.) ISO Material Condition Tensile Hardness MaterialStrength (Kpsi)HBNumber Non - Alloy Steels <0.25% C Annealed 61 125 1 Steel Castings =>0.25% C Annealed 94 190 2 Free Machining Steel <0.55% C Quenched & Tempered 123 250 3 =>0.55% C Annealed 109 220 4 =>0.55% C Quenched & Tempered 145 300 5 P Low - Alloy Steels and Steel Castings Annealed 87 200 6 (less than 5% of alloying elements) 135 275 7 Quenched & Tempered 145 300 8 174 350 9 High - Alloy Steels, Steel Annealed 99 200 10 Castings & Tool Steels Quenched & Tempered 160 325 11 Stainless Steels and Ferritic/Martensitic 99 200 12 M Stainless Steel Castings Martensitic 119 240 13 Austenitic & P.H. 87 180 14 Nodular Cast Iron (GGG) Ferritic / Pearlitic 180 15 Pearlitic 260 16 K Grey Cast Iron (GG) Ferritic 160 17 Pearlitic 250 18 Malleable Cast Iron Ferritic 130 19 Pearlitic 230 20 Aluminum wrought alloy As cast 60 21 Forged 100 22 Cast Aluminum alloyed <=12% Si As cast 75 23 Forged 90 24 N > 12% Si High Temperature 130 25 Free Cutting 110 26 Copper Alloys Brass 90 27 Electrolitic Copper 100 28 Non Metallic Duroplastics & Fiberplastics 29 Hard Rubber 30 Fe Based Annealed 200 31 Cured 280 32 S High Temp Alloys Ni or Co BasedAnnealedCured 250 3335034 Cast 320 35 Titanium and Ti Alloys 58 36 Alpha+Beta alloys cured 152 37 Hardened Steel 55 HRc 38 H Chilled Cast Iron Cast 60 HRc 3940040 Cast Iron Hardened 55 HRc 41 670

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021