Общий каталог Ingersoll 2011 - страница 371

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

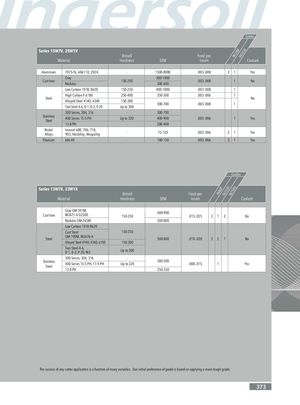

IN30MIIINNN11455034P00 IN1030 Grades Series 15W7V, 25W1V Brinell Feed per Material Hardness SFM Insert Coolant Aluminum 7075-T6, 6061-T2, 2024 - 1500-8000 .003-.008 2 1 Yes Gray 300-1000 Cast Iron 150-250 .003-.008 1 No Nodular 300-600 Low Carbon 1018, 8620 150-250 400-1000 .003-.008 1 High Carbon F-6180 250-400 350-500 .003-.006 1 Steel No Alloyed Steel 4140, 4340 150-300 300-700 .003-.008 1 Tool Steel A-6, D-1, D-2, P-20 Up to 300 300 Series, 304, 316 - 300-700 StSaitneleels s 400 Series 15-5 PH Up to 320 400-900 .003-.006 1 Yes 13-8 PH - 200-400 Nickel Inconel 600, 706, 718,Alloys 903, Hastelloy, Waspalloy- 75-120 .003-.006 2 1 Yes Titanium 6AL-4V - 100-150 .003-.006 2 1 Yes Grades Series 13W7X, 23W1X Brinell Feed per Material Hardness SFM Insert Coolant Cast Iron MGr3aAy7G1M-A-2G4215M0,0 150-250 600-900 .015-.025 3 1 2 No Nodular GM-245M 500-800 Low Carbon 1018-8620 Cast Steel 150-250 Steel GM-190M, M3A76-A 500-800 .010-.020 3 2 1 No Alloyed Steel 4140, 4340, 6150 150-300 Tool Steel A-6, D-1, D-2, P-20, W2 Up to 300 300 Series, 304, 316 - StSaitneleels s 400 Series 15-5 PH, 17-4 PH 300-500Up to 320 .008-.015 1 Yes 13-8 PH - 250-350 The success of any cutter application is a function of many variables. Our initial preference of grade is based on applying a more tough grade. 373

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021