Общий каталог Ingersoll 2011 - страница 1353

Навигация

- 0003 Table of Contents

- 0006 End Mills

- 0064 Long Edge

- 0104 0Deg Face Mills

- 0160 Face Mills

- 0202 Slotters

- 0218 Form Mills

- 0236 Profile Mills

- 0302 Milling Tech

- 0384 Solid Carbide

- 0448 Solid Carbide Tech

- 0474 Holemaking & Thread Milling

- 0666 Holemaking & Thread Milling Tech

- 0720 Innofit Top On Toolholders

- 0738 HSK Toolholders

- 0774 CAT Toolholders

- 0796 BT Toolholders

- 0816 Adaptions Accessories

- 0872 Turning Inserts

- 1024 Turning Holders

- 1144 Turning Tech

- 1174 Threading Inserts

- 1242 Threading Holders

- 1256 Threading Tech

- 1268 T-Clamp

- 1344 T-Clamp Tech

- 1376 T-CAP

- 1388 T-CAP Tech

- 1394 Product_Index

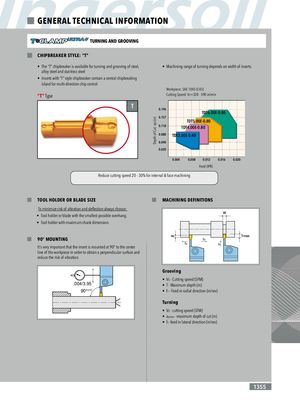

Depth of Cut ap (in) GENERAL TECHNICAL INFORMATION TURNING AND GROOVING CHIPBREAKER STYLE: "T" • The “T” chipbreaker is available for turning and grooving of steel, • Machining range of turning depends on width of inserts. alloy steel and stainless steel • Inserts with “T” style chipbreaker contain a central chipbreaking island for multi-direction chip control Workpiece: SAE 1045 (C45) “T” Type Cutting Speed: Vc=328 - 590 in/min T 0.196 TDT6.00E-0.80 0.157 TDT5.00E-0.80 0.118 TDT4.00E-0.80 0.080 TDT3.00E-0.40 0.040 0.020 0.004 0.008 0.012 0.016 0.020 Feed (IPR) Reduce cutting speed 20 - 30% for internal & face machining TOOL HOLDER OR BLADE SIZE MACHINING DEFINITIONS To minimize risk of vibration and deflection always choose: • Tool holder or blade with the smallest possible overhang. • Tool holder with maximum shank dimension. 90° MOUNTING It’s very important that the insert is mounted at 90° to the center line of the workpiece in order to obtain a perpendicular surface and reduce the risk of vibration. Grooving • Vc - Cutting speed (SFM) .004/3.95 • T - Maximum depth (in) 90°±10´ • f1 - Feed in radial direction (in/rev) Turning • Vc - cutting speed (SFM) • apmax - maximum depth of cut (in) • f2 -feed in lateral direction (in/rev) 1355

Общий каталог Ingersoll 2016 - 2017

Общий каталог Ingersoll 2016 - 2017 Общий каталог Ingersoll 2014

Общий каталог Ingersoll 2014 Каталог Ingersoll инструмент для нарезания резьбы

Каталог Ingersoll инструмент для нарезания резьбы Общий каталог Ingersoll 2013 - 2014

Общий каталог Ingersoll 2013 - 2014 Каталог Ingersoll новинки 2021

Каталог Ingersoll новинки 2021