Общий каталог Harlingen 2024 - страница 7

Навигация

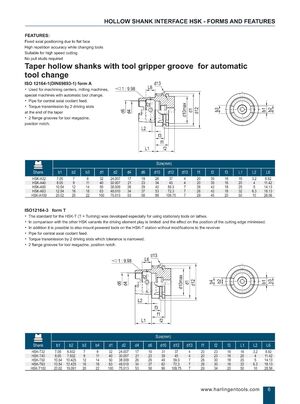

HOLLOW SHANK INTERFACE HSK - FORMS AND FEATURES FEATURES: Fixed axial positioning due to flat face High repetition accuracy while changing tools Suitable for high speed cutting No pull studs required Taper hollow shanks with tool gripper groove for automatic tool change ISO 12164-1( DIN69893-1) form A L6 O 1 : 9.98 • Used for machining centers , milling machines special machines with automatic tool change. • Pipe for central axial coolant feed. d13 I • Torque transmission by 2 driving slots at the end of the taper • 2 flange grooves for tool magazine, CO X CD CNJ E - xj o -o i _ I I- r _U CO r O CNJ CO Q Q " “O " O position notch. L2 f3 f1 L1 (Z Size (mm) Shank 0 0 0 a a HSK -A32 HSK - A40 HSK -A50 HSK -A63 HSK-A 100 7.05 8.05 10.54 12.54 20.02 7 9 12 16 20 9 11 14 18 22 32 40 50 63 100 24.007 30.007 38.009 48.010 75.013 17 21 26 34 53 m d10 d12 d13 19 23 29 37 58 26 34 42 53 88 37 45 59.3 72.3 109.75 4 4 7 7 7 L1 35 35 42 42 45 20 20 26 26 29 16 16 18 18 20 16 20 25 32 50 Lfi 3.2 4 5 6.3 10 8.92 11.42 14.13 18.13 28.56 IS012164-3 form T • The standard for the HSK-T ( T = Turning) was developed especially for using stationary tools on lathes. • In comparison with the other HSK variants the driving element play is limited and the effect on the position of the cutting edge minimised. • In addition it is possible to also mount powered tools on the HSK-T station without modifications to the revolver • Pipe for central axial coolant feed. • Torque transmission by 2 driving slots which tolerance is narrowed. • 2 flange grooves for tool magazine, position notch. <3 1 CD o L6 : 9.98 -xr a d13 1 e® 4 X CD E C r . JJ i r i _ CD CNJ XT O | CO Q " TD Q _Q " O L2 f3 f1 f2 L1 Size(mm) Shank if] a a HSK -T32 HSK-T40 HSK-T50 HSK-T63 HSK -T100 7.05 8.05 10.54 12.54 20.02 6.932 7.932 10.425 12.425 19.091 7 9 12 16 20 9 11 14 18 22 a a 32 40 50 63 100 24.007 30.007 38.009 48.010 75.013 17 21 26 34 53 m d10 d12 d13 19 23 29 37 58 31 39 49 62 99 37 45 59.3 72.3 109.75 4 4 7 7 7 L1 20 20 26 26 29 23 23 30 30 34 16 16 18 18 20 16 20 25 32 50 a 3.2 4 5 6.3 10 www. harlingentools . com 8.92 11.42 14.13 18.13 28.56

Каталог Harlingen инструмент для пресс-форм 2024

Каталог Harlingen инструмент для пресс-форм 2024 Каталог Harlingen PSC-оправки (CAPTO совместимые)

Каталог Harlingen PSC-оправки (CAPTO совместимые)