Каталог Guhring сверла со сменными пластинами - страница 5

Навигация

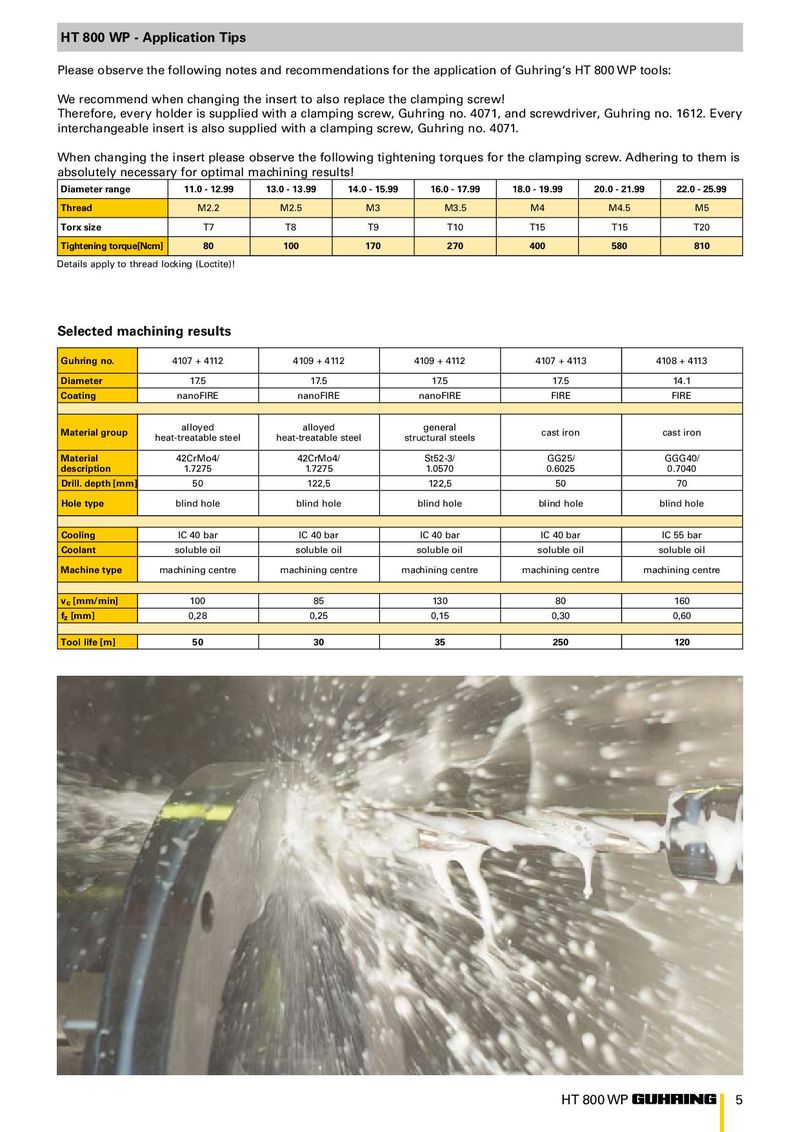

HT 800 WP - Application Tips Please observe the following notes and recommendations for the application of Guhring‘s HT 800 WP tools: We recommend when changing the insert to also replace the clamping screw! Therefore, every holder is supplied with a clamping screw, Guhring no. 4071, and screwdriver, Guhring no. 1612. Every interchangeable insert is also supplied with a clamping screw, Guhring no. 4071. When changing the insert please observe the following tightening torques for the clamping screw. Adhering to them is absolutely necessary for optimal machining results! Diameter range 11.0 - 12.99 13.0 - 13.99 14.0 - 15.99 16.0 - 17.99 18.0 - 19.99 20.0 - 21.99 22.0 - 25.99 Thread M2.2 M2.5 M3 M3.5 M4 M4.5 M5 Torx size T7 T8 T9 T10 T15 T15 T20 Tightening torque[Ncm] 80 100 170 270 400 580 810 Details apply to thread locking (Loctite)! Selected machining results Guhring no. 4107 + 4112 4109 + 4112 4109 + 4112 4107 + 4113 4108 + 4113 Diameter 17.5 17.5 17.5 17.5 14.1 Coating nanoFIRE nanoFIRE nanoFIRE FIRE FIRE alloyed alloyed general Material group cast iron cast iron heat-treatable steel heat-treatable steel structural steels Material 42CrMo4/ 42CrMo4/ St52-3/ GG25/ GGG40/ description 1.7275 1.7275 1.0570 0.6025 0.7040 Drill. depth [mm] 50 122,5 122,5 50 70 Hole type blind hole blind hole blind hole blind hole blind hole Cooling IC 40 bar IC 40 bar IC 40 bar IC 40 bar IC 55 bar Coolant soluble oil soluble oil soluble oil soluble oil soluble oil Machine type machining centre machining centre machining centre machining centre machining centre v c [mm/min] 100 85 130 80 160 f z [mm] 0,28 0,25 0,15 0,30 0,60 Tool life [m] 50 30 35 250 120 HT 800 WP 5

Каталог Guhring пластины PKD и CBN

Каталог Guhring пластины PKD и CBN Основной каталог Guhring 2011

Основной каталог Guhring 2011 Каталог Guhring резьбонарезной инструмент

Каталог Guhring резьбонарезной инструмент Каталог Guhring зенкеры и зенковки

Каталог Guhring зенкеры и зенковки Каталог Guhring резьбонарезной инструмент 2010

Каталог Guhring резьбонарезной инструмент 2010 Каталог Guhring высокопроизводительный инструмент по отличной цене SuperLine

Каталог Guhring высокопроизводительный инструмент по отличной цене SuperLine