Каталог FANAR цельные твердосплавные фрезы - страница 4

Навигация

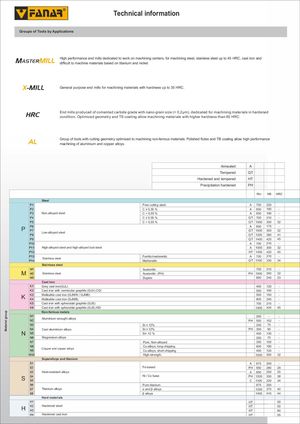

Technical information Groups of Tools by Applications High performance end mills dedicated to work on machining centers, for machining steel, stainless steel up to 45 HRC, cast iron and MASTERMILL difficult to machine materials based on titanium and nickel. X-MILL General purpose end mills for machining materials with hardness up to 35 HRC. End mills produced of comented carbide grade with nano-grain size (< 0,2μm), dedicated for machining materials in hardened HRC condition. Optimized geometry and TS coating allow machining materials with higher hardness than 65 HRC. Group of tools with cutting geometry optimized to machining non-ferrous materials. Polished flutes and TB coating allow high performance AL. machining of aluminium and copper alloys. Annealed A Tempered QT Hardened and tempered HT Precipitation hardened PH Rm HB HRC StSatleel P1 Free cutting steel A 750 220 P2 C ≤ 0,55 % A 650 190 - P3 Non-alloyed steel C > 0,55 % A 650 190 - P4 C ≤ 0,55 % QT 700 210 - P5 C > 0,55 % QT 1000 300 32 P6 A 600 175 - P P7 QT 1000 300 32 Low-alloyed steel P8 QT 1200 380 41 P9 QT 1400 420 45 P10 A 700 210 - P11 High-alloyed steel and high-alloyed tool steel A 1000 300 32 P12 HT 1400 420 45 P13 Ferritic/martensitic A 700 210 - Stainless steel P14 Martensitic QT 1100 330 34 Stainless steel M1 Austenitic 700 210 - M M2 Stainless steel Austenitic (PH) PH 1000 300 32 M3 Duplex 800 240 23 Cast iron K1 Grey cast iron(GJL) 400 120 - K2 Cast iron with vermicular graphite (GJV) CGI 550 160 - K3 Malleable cast iron (GJMW / GJMB)KK4Malleable cast iron (GJMB) 500 150 -800240- K5 Cast iron with spheroidal graphite (GJS) 700 210 - K6 Cast iron with spheroidal graphite (GJS) ADI 1400 420 45 Non-ferrous metals N1 200 - - Aluminium wrought alloys N2 PH 500 152 - N3 Si ≤ 12% 250 75 - N4 Cast aluminium alloys Si ≤ 12% PH 300 90 - N N5 Si> 12 % 450 130 - N6 Magnesium alloys 250 70 - N7 Pure, Non-alloyed 350 100 - N8 Cu-alloys, long-chipping 600 180 - Copper and copper alloys N9 Cu-alloys, short-chipping 400 120 - N10 High-strength, 1000 300 32 Superalloys and titanium S1 A 675 200 - S2 Fe-based PH 950 280 29 S3 Heat-resistant alloys A 850 250 25 S S4S5 Ni / Co base PH 1200 350 38C110032034 S6 Pure titanium 675 200 - S7 Titanium alloys α and β alloys 1250 375 40 S8 β alloys 1400 410 44 Hard materials H1 HT 50 H2 Hardened steelHH3 HT 55HT60 H4 Hardened cast iron HT 55 Material group

Общий каталог FANAR 2018

Общий каталог FANAR 2018 Общий каталог FANAR 2021

Общий каталог FANAR 2021