Каталог Erojet резьбонарезные пластины и державки - страница 60

Навигация

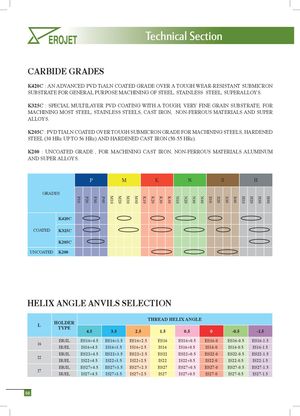

P10 P20 P30 P40 M10 M20 M30 M40 K10 K20 K30 K40 N10 N20 N30 N40 S10 S20 S30 S40 H10 H20 H30 H40 Technical Section CARBIDE GRADES K420C : AN ADVANCED PVD TiALN COATED GRADE OVER A TOUGH WEAR-RESISTANT SUBMICRON SUBSTRATE FOR GENERAL PURPOSE MACHINING OF STEEL, STAINLESS STEEL, SUPERALLOYS. K325C : SPECIAL MULTILAYER PVD COATING WITH A TOUGH, VERY FINE GRAIN SUBSTRATE, FOR MACHINING MOST STEEL, STAINLESS STEELS, CAST IRON, NON-FERROUS MATERIALS AND SUPER ALLOYS. K205C : PVD TIALN COATED OVER TOUGH SUBMICRON GRADE FOR MACHINING STEELS, HARDENED STEEL (30 HRc UP TO 56 HRc) AND HARDENED CAST IRON (50-55 HRc). K200 : UNCOATED GRADE , FOR MACHINING CAST IRON, NON-FERROUS MATERIALS ALUMINUM AND SUPER ALLOYS. P M K N S H GRADES K420C COATED K325C K205C UNCOATED K200 HELIX ANGLE ANVILS SELECTION L HOLDERTYPE 4.5 3.5 THREAD HELIX ANGLE2.51.50.5 0 -0.5 -1.5 16 ER/IL ES16+4.5 ES16+3.5 ES16+2.5 ES16 ES16+0.5 ES16-0 ES16-0.5 ES16-1.5IR/ELIS16+4.5IS16+3.5IS16+2.5IS16IS16+0.5IS16-0IS16-0.5IS16-1.5 22 ER/IL ES22+4.5 ES22+3.5 ES22+2.5 ES22 ES22+0.5 ES22-0 ES22-0.5 ES22-1.5 IR/EL IS22+4.5 IS22+3.5 IS22+2.5 IS22 IS22+0.5 IS22-0 IS22-0.5 IS22-1.5 ER/IL ES27+4.5 ES27+3.5 ES27+2.5 ES27 ES27+0.5 ES27-0 ES27-0.5 ES27-1.5 27 IR/EL IS27+4.5 IS27+3.5 IS27+2.5 IS27 IS27+0.5 IS27-0 IS27-0.5 IS27-1.5 58

Каталог Erojet монолитные резбофрезы

Каталог Erojet монолитные резбофрезы