Каталог Duemmel общий 2022 - страница 140

Навигация

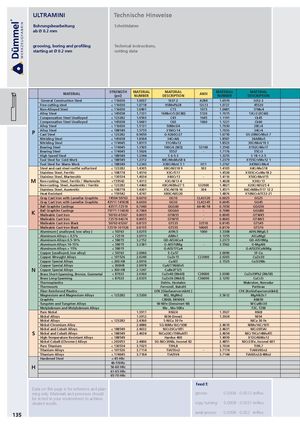

ULTRAMINI Technische Hinweise Bohrungsbearbeitung Schnittdaten ab Ø 0.2 mm grooving, boring and profiling Technical instructions, starting at Ø 0.2 mm cutting data MATERIAL STRENGTH MATERIAL MATERIAL(psi)NUMBERDESCRIPTIONANSI MATERIALNUMBER MATERIALDESCRIPTION General Construction Steel < 116030 1.0037 St37-2 A284 1.0570 St52-3 Free-cutting steel < 116030 1.0718 9SMnPb28 12L13 1.0727 45S20 Non-Alloyed Steel < 116030 1.0401 C15 1015 1.0481 17Mn4 Alloy Steel < 145038 1.7331 16MnCr5 (EC80) 5120 1.7015 13Cr3 (EC60) Compensation Steel Unalloyed < 123282 1.0503 C45 1045 1.1191 Ck45 Compensation Steel Unalloyed < 145038 1.0601 C60 1060 1.1221 Ck60 Alloy Steel < 116030 1.5131 50MnSi4 1.7030 28Cr4 P Alloy SteelCast Steel < 188549 1.5755 31NiCr14 1.7033 34Cr4< 1232820.9650G-X260Cr271.6750GS-20NiCrMo3 7 Nitriding Steel < 145038 1.8504 34CrAl6 1.8507 34AlMo5 Nitriding Steel < 174045 1.8515 31CrMo12 1.8523 39CrMoV19 3 Bearing Steel < 174045 1.3505 100Cr6 (W3) 52100 1.3543 X192CrMo17 Bearing Steel < 174045 1.5026 55Si7 - 1.7176 55Cr3 High Speed Steel < 188549 1.3344 S 6-5-3 1.3255 S 18-1-2-5 Tool Steel for Cold Work < 188549 1.2312 40CrMnMoS8 6 1.2379 X155CrVMo12 1 Tool Steel for Warm Work < 188549 1.2343 X38CrMoV 5 1 H11 1.2767 X45NiCrMo4 Steel and cast steel rostfei sulfurized < 123282 1.4305 X8CrNiS18 9 303 1.4105 X4CrMoS18 Stainless Steel, Ferritic < 108778 1.4510 X3CrTi17 1.4528 X105CrCoMo18 2 Stainless Steel, Martensitic < 130534 1.4034 X46Cr13 - 1.4116 X50CrMoV15 M Non-rusting. Steel, Ferritic / Martensite <159542 1.4313 X3CrNi13-4 1.4028 X30Cr13 Non-rusting. Steel, Austenitic / Ferritic < 123282 1.4460 X8CrNiMo27 5 S32900 1.4821 X20CrNiSi25 4 Stainless Steel, Austenitic < 108778 1.4301 X5CrNi18-10 304 1.4571 X6CrNiMoTi17 12 2 Heat Resistant < 159542 1.4747 X80CrNiSi20 1.4876 X10NiCrAlTi32-21 Gray Cast Iron with Lamellar Graphite 14504-50763 0.6010 GG10 CLASS20 0.6025 GG25 Gray Cast Iron with Lamellar Graphite 43511-145038 0.6030 GG30 CLASS45 0.6045 GG45 Ball Graphite Castings 43511-72519 0.7040 GGG40 60-40-18 0.7050 GGG50 K Ball Graphite CastingsMalleable Cast Iron 79771-116030 0.7060 GGG60 - 0.7080 GGG8050763-653670.8035GTW35-0.8045GTW45 Malleable Cast Iron 72519-94274 0.8055 GTW55 - 0.8065 GTW65 Malleable Cast Iron Black 50763-65267 0.8135 GTS35 32510 0.8145 GTS45 Malleable Cast Iron Black 72519-101526 0.8155 GTS55 50005 0.8170 GTS70 Aluminum ( unalloyed, low alloy ) < 50763 3.0255 Al99,5 1000 3.3308 Al99,9Mg0,5 Aluminum Alloys < 0,5% < 72519 3.0515 AlMn1 3.1355 AlCuMg2 Aluminum Alloys 0,5-10% < 58015 3.2152 GD-AlSi6Cu4 3.2373 GD-AlSi9Mg Aluminum Alloys 10-15% < 58015 3.2381 G-AlSi10Mg - 3.5562 G-MgAl6 Aluminum Alloys > 15% < 58015 G-AlSi17Cu4 G-AlSi25CuNiMg Copper (unalloyed, low alloy) < 50763 2.0060 E-Cu57 2.0090 SF-Cu Copper Wrought Alloys < 101526 2.0240 CuZn15 C23000 2.0265 CuZn30 Copper Special Alloys < 200 HB 2.0916 CuAl5 2.1525 CuSi3Mn Copper Special Alloys < 300HB 2.0978 CuAl11Ni6Fe5 N Copper Special Alloys > 300 HB 2.1247 CuBe2F125 Brass Short-Spanning, Bronze, Gunmetal < 87023 2.0360 CuZn40 (Ms60) C28000 2.0380 CuZn39Pb2 (Ms58) Brass Long-Spanning < 87023 2.0335 CuZn36 (Ms63) C36000 2.1293 CuCrZr Thermoplastics Delrin, Hostalen Makrolon, Novodur Thermosets Ferrozell, Bakelit Pertinax Fiber Reinforced Plastics GFK (Glasfaserverstärkt ) CFK (Kohlefaserverstärkt) Magnesium and Magnesium Alloys < 123282 3.5200 M2, MgMn2 3.5612 MgAl6Zn1 Graphite C8000, R8500X R8650 Tungsten and Tungsten Alloys W-NiFe (Densimet W) W-Cu80/20 Molybdenum and Molybdenum Alloys Mo , Mo-50Re TZC, TZM Pure Nickel 1.3911 RNi24 1.3927 RNi8 Nickel Alloys 1.3912 Ni36 (Invar) 1.3924 Ni54 Nickel Alloys < 123282 2.4360 S-NiCu 30 Fe NiCu 30 Fe Nickel-Chromium Alloy 2.4886 SG-NiMo16Cr16W 2.4610 NiMo16Cr16Ti Nickel and Cobalt Alloys < 188549 2.4632 NiCr20Co18Ti 2.4631 NiCr20TiAl S Nickel and Cobalt Alloys < 188549 2.4634 NiCo20Cr15MoAlTi 2.4654 NiCr19Co14Mo4Ti High-Temperature Resistant Alloys < 188549 Hardox 400 1.4939 X12CrNiMo12 Nickel-Cobalt-(Chrome-) Alloys < 203053 2.4806 SG-NiCr20Nb, Inconel 82 2.4851 NiCr23Fe, Inconel 601 Pure Titanium < 130534 3.7025 Ti99,8 3.7034 Ti99,7 Titanium Alloys < 101526 3.7114 TiAl5Sn2 - 3.7174 TiAl6V6Sn2 Titanium Alloys < 174045 3.7164 TiAl5V4 3.7144 TiAl6Sn2Zr4Mo2 Hardened Steel < 45 HRc 46-55HRc H 56-60 HRc 61-65 HRc 65-70 HRc feed f: Data on this page is for reference and plan- ning only. Materials and processes should groove: 0.0004 - 0.0012 in/Rev. be tested in your environment to achieve desired results. copy turning: 0.0008 - 0.0031 in/Rev. 135 axial groove: 0.0008 - 0.002 in/Rev.

Общий каталог Dümmel 2014

Общий каталог Dümmel 2014 Каталог Dümmel дополнение 2017

Каталог Dümmel дополнение 2017 Каталог Dümmel дополнение 2018

Каталог Dümmel дополнение 2018 Общий каталог Dümmel 2015

Общий каталог Dümmel 2015