Каталог Dormer Pramet токарная обработка 2021 - 2022 - страница 340

Навигация

- Содержание

- Алфавитный указатель

- WMG & ISO 13399

- Точение ISO

- Позитивные пластины

- CC

- CCGT

- CCMT

- CCMW

- CCGW CBN

- SCAC(RL) EXT

- SCBC(RL) EXT

- SCDCR EXT

- SCFC(RL) EXT

- SCLC(RL) EXT

- C.-SCLC(RL) EXT

- SCFC(RL) INT

- SCKC(RL) INT

- SCLC(RL) INT

- SCXC(RL) INT

- C.-SCLC(RL) INT

- CP

- CPGX

- DC

- DCGT

- DCMT

- DCMW

- DCGW CBN

- DCMW PCD

- SDJC(RL) EXT

- SDNCN EXT

- C.-SDJC(RL) EXT

- C.-SDNCN EXT

- SDQC(RL) INT

- SDUC(RL) INT

- SDUC(RL)-E INT

- SDZC(RL) INT

- C.-SDUC(RL) INT

- EC

- ECGT

- ECMT

- ECMW

- SEGC(RL) EXT

- SEUC(RL) INT

- EP

- EPGX

- EPMT

- SELP(RL) INT

- SELP(RL)-E INT

- SEUP(RL) INT

- SEXP(RL) INT

- SEXP(RL)-E INT

- RC

- RCGT

- RCMT

- RCMW

- RCMX

- RCGX CER

- PRDCN EXT

- PRSC(RL) EXT

- SRDC(RL) EXT

- SRDCN EXT

- SRSC(RL) EXT

- C.-SRDCN EXT

- KHP-RSC(RL)

- DKH(RL)

- SC

- SCGT

- SCMT

- SCMW

- SSBC(RL) EXT

- SSDCN EXT

- SSKC(RL) EXT

- KHS-SBC(RL)

- DKH(RL)

- SSSC(RL) INT

- SP

- SPMR

- SPUN

- SPGN CER

- TC

- TCGT

- TCMT

- TCMW

- TCGW CBN

- STFC(RL) EXT

- STFC(RL)-A EXT

- STJC(RL) EXT

- STFC(RL) INT

- STFC(RL)-E INT

- TP

- TPGX

- TPMR

- TPUN

- TPGN CER

- VB

- VBMT

- VBGW CBN

- SVHB(C)(RL) EXT

- SVJB(C)(RL) EXT

- SVPB(C)(RL) EXT

- SVVB(C)N EXT

- SVXB(C)(RL) EXT

- C.-SVHB(RL) EXT

- C.-SVJB(RL) EXT

- C.-SVVBN EXT

- SVJB(RL) INT

- SVQB(C)(RL) INT

- SVUB(C)(RL) INT

- C.-SVQB(RL) INT

- VC

- VCGT

- VCGW

- VCGX

- VCMT

- VCMW

- VCMW PCD

- SVAC(RL)-DC EXT

- SVGC(RL) EXT

- SVHB(C)(RL) EXT

- SVJB(C)(RL) EXT

- SVJC(RL)-DC EXT

- SVPB(C)(RL) EXT

- SVVB(C)N EXT

- SVXB(C)(RL) EXT

- C.-SVHB(RL) EXT

- C.-SVJB(RL) EXT

- C.-SVVBN EXT

- SVJB(RL) INT

- SVLC(RL) INT

- SVQB(C)(RL) INT

- SVUB(C)(RL) INT

- SVXC(RL) INT

- SVXC(RL)-E INT

- C.-SVQB(RL) INT

- WC

- WCGT

- WCGX

- WCMT

- SWLC(RL) EXT

- SWLC(RL) INT

- SWUC(RL) INT

- SWUC(RL)-E INT

- Негативные пластины

- CN

- CNGG

- CNMA

- CNMG

- CNMM

- CNGA CER

- CNGN CER

- CNGA CBN

- DCBN(RL) EXT

- DCKN(RL) EXT

- DCLN(RL) EXT

- PCBN(RL) EXT

- PCKN(RL) EXT

- PCLN(RL) EXT

- C.-DCLN(RL) EXT

- KHP-CBN(RL)

- KHP-CLN(RL)

- DKH(RL)

- DCLN(RL) INT

- PCLN(RL) INT

- C.-DCLN(RL) INT

- DN

- DNMA

- DNMG

- DNMM

- DNGA CER

- DNGN CER

- DNGA CBN

- DDJN(RL) EXT

- PDJN(RL) EXT

- PDNN(RL) EXT

- PDXN(RL) EXT

- C.-DDJN(RL) EXT

- C.-DDNNN EXT

- C.-DDUN(RL) EXT

- DDUN(RL) INT

- PDUN(RL) INT

- C.-DDUN(RL) INT

- KN

- KNUX

- CKJN(RL) EXT

- LN

- LNUX 40, LN.X 50

- PLBN(RL) EXT

- KHP-LBN(RL)

- DKH(RL)

- RN

- RNMG

- RNGN CER

- DRSN(RL) EXT

- PRSN(RL) EXT

- C.-DRSN(RL) EXT

- SN

- SNMA

- SNMG

- SNMM

- SNMX

- SNGA CER

- SNGN CER

- DSBN(RL) EXT

- DSDNN EXT

- DSKN(RL) EXT

- DSSN(RL) EXT

- PSBN(RL) EXT

- PSDNN EXT

- PSKN(RL) EXT

- PSSN(RL) EXT

- C.-DSDNN EXT

- C.-DSKN(RL) EXT

- C.-DSRN(RL) EXT

- C.-DSSN(RL) EXT

- KHP-SBN(RL)

- KHP-SSN(RL)

- DKH(RL)

- PSKN(RL) INT

- TN

- TNMA

- TNMG

- TNMM

- TNGA CER

- TNGN CER

- TNGA CBN

- DTFN(RL) EXT

- DTGN(RL) EXT

- MTJN(RL) EXT

- PTFN(RL) EXT

- PTGN(RL) EXT

- PTTN(RL) EXT

- C.-DTJN(RL) EXT

- DTFN(RL) INT

- PTFN(RL) INT

- C.-DTFN(RL) INT

- VN

- VNMG

- VNGA CER

- VNGA CBN

- DVJN(RL) EXT

- DVPN(RL) EXT

- MVJN(RL) EXT

- C.-DVJN(RL) EXT

- DVUN(RL) INT

- WN

- WNMA

- WNMG

- WNMM

- WNGA CBN

- DWLN(RL) EXT

- MWLN(RL) EXT

- PWLN(RL) EXT

- C.-DWLN(RL) EXT

- DWLN(RL) INT

- PWLN(RL) INT

- C.-DWLN(RL) INT

- Геометрии пластин

- Точение канавок и отрезка

- GL

- GL. D - GM

- GL. D - MM

- GL. D - PM

- GL. D - PR

- GLSF(RL) EXT

- GLSF(RL) EXT-G

- GLSF(RL) EXT-S

- GLS B

- DU, D

- Глубина обработки

- LC 13

- LCMF 13 - CM

- LCMF 13 - F

- LCMF 13 - MP

- LCMR 13 - F

- LCMR 13 - MP

- GG.(RL) INT

- GFIL-L AXIAL

- GFIL-R AXIAL

- GFIR-L AXIAL

- GFIR-R AXIAL

- GFML-L AXIAL

- GFML-R AXIAL

- GFMR-L AXIAL

- GFMR-R AXIAL

- GGI(RL)-90 AXIAL

- LC 16, 30

- LCMF 16 - CM

- LCMF 16, LCMF 30 - F

- LCMF 16 - M

- LCMF 16, LCMF 30 - MP

- LCMR 16 - CM

- LCMR 16, LCMR 30 - F

- LCMR 16 - M

- LCMR 16 - MP

- GFI(RL) EXT

- GFM(RL) EXT

- XLCCN B

- DU, D

- XLCCN 25 BS

- MS-EN

- GFIL-L AXIAL

- GFIL-R AXIAL

- GFIR-L AXIAL

- GFIR-R AXIAL

- GFML-L AXIAL

- GFML-R AXIAL

- GFMR-L AXIAL

- GFMR-R AXIAL

- GGI(RL)-90 AXIAL

- LC 20

- LCMF 20 - F1

- LCMF 20 - M2

- LCMF 20 - MP

- GFK(RL) EXT

- LFMX

- LFMX - F1

- LFMX - F2

- LFMX - M2

- XLCFN B

- DU, D

- XLCF(NRL) BS

- XLXFL BS AXIAL

- MS-EN

- LFUX

- LFUX

- XLCF(RL)

- XLCFN B LFUX

- DU, D

- X 61

- X 61

- X 61 R

- P61(RL) EXT

- P61(RL) INT

- X 61-1

- X 61-1

- X 61 R-1

- P61S(RL)-1 INT

- TN

- TN R EXT

- TN R INT

- TN ZZ EXT

- TN ZZ INT

- SE(RL)

- SI(RL)

- Точение резьбы

- Пластины

- TN M EXT

- TN M INT

- TN MJ EXT

- TN 60° PP EXT

- TN 60° PP INT

- TN 60°-S PP EXT

- TN 60°-S PP INT

- TN UN EXT

- TN UN INT

- TN UNJ EXT

- TN W EXT

- TN W INT

- TN 55° PP EXT

- TN 55° PP INT

- TN BSPT EXT

- TN BSPT INT

- TN NPT EXT

- TN NPT INT

- TN TR EXT

- TN TR INT

- TN TR-S EXT

- TN TR-S INT

- TN ACME EXT

- TN ACME INT

- TN STACME EXT

- TN STACME INT

- TN API RD EXT

- TN API RD INT

- TN RD EXT

- TN RD INT

- Державки

- SE(RL)

- SE(RL)-S

- SI(RL)

- SI(RL)-S

- Подкладные пластины

- Глубина врезаний

- Строгание

- HZ

- HZ-2

- PHZ

- PHZ-2

- Техническая информация

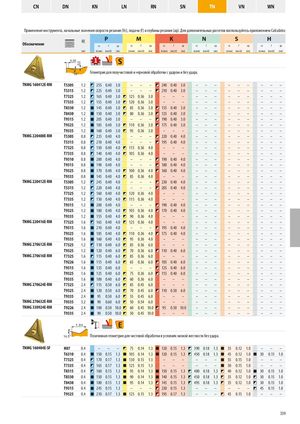

CN DN KN LN RN SN TN VN WN Применение инструмента, начальные значения скорости резания (Vc), подачи (f) и глубины резания (ap). Для дополнительных расчетов воспользуйтесь приложением Calculator. Обозначение RE P M K N S Hvcfapvcfapvcfapvcfapvcfapvcfap (мм) (м/мин) (мм/об) (мм) (м/мин) (мм/об) (мм) (м/мин) (мм/об) (мм) (м/мин) (мм/об) (мм) (м/мин) (мм/об) (мм) (м/мин) (мм/об) (мм) Геометрия для получистовой и черновой обработки с ударом и без удара. TNMG 160412E-RM T5305 1.2 255 0.40 3.0 – – – 240 0.40 3.0 – – – – – – – – – T5315 1.2 225 0.40 3.0 – – – 210 0.40 3.0 – – – – – – – – – T7325 1.2 165 0.40 3.0 125 0.36 3.0 – – – – – – – – – – – – T7335 1.2 155 0.40 3.0 120 0.36 3.0 – – – – – – – – – – – – T8330 1.2 145 0.40 3.0 85 0.36 3.0 135 0.40 3.0 – – – – – – – – – T8430 1.2 150 0.40 3.0 80 0.36 3.0 125 0.40 3.0 – – – – – – – – – T9315 1.2 205 0.40 3.0 – – – 190 0.40 3.0 – – – – – – – – – T9325 1.2 185 0.40 3.0 110 0.36 3.0 175 0.40 3.0 – – – – – – – – – T9335 1.2 160 0.40 3.0 95 0.36 3.0 – – – – – – – – – – – – TNMG 220408E-RM T5305 0.8 235 0.40 4.0 – – – 220 0.40 4.0 – – – – – – – – – T5315 0.8 210 0.40 4.0 – – – 195 0.40 4.0 – – – – – – – – – T7325 0.8 150 0.40 4.0 115 0.36 4.0 – – – – – – – – – – – – T7335 0.8 140 0.40 4.0 105 0.36 4.0 – – – – – – – – – – – – T9310 0.8 200 0.40 4.0 – – – 190 0.40 4.0 – – – – – – – – – T9315 0.8 190 0.40 4.0 – – – 180 0.40 4.0 – – – – – – – – – T9325 0.8 170 0.40 4.0 100 0.36 4.0 160 0.40 4.0 – – – – – – – – – T9335 0.8 145 0.40 4.0 85 0.36 4.0 – – – – – – – – – – – – TNMG 220412E-RM T5305 1.2 245 0.40 4.0 – – – 230 0.40 4.0 – – – – – – – – – T5315 1.2 220 0.40 4.0 – – – 205 0.40 4.0 – – – – – – – – – T7325 1.2 160 0.40 4.0 120 0.36 4.0 – – – – – – – – – – – – T7335 1.2 150 0.40 4.0 115 0.36 4.0 – – – – – – – – – – – – T9315 1.2 200 0.40 4.0 – – – 190 0.40 4.0 – – – – – – – – – T9325 1.2 180 0.40 4.0 105 0.36 4.0 170 0.40 4.0 – – – – – – – – – T9335 1.2 155 0.40 4.0 90 0.36 4.0 – – – – – – – – – – – – TNMG 220416E-RM T7325 1.6 165 0.40 4.0 125 0.36 4.0 – – – – – – – – – – – – T9315 1.6 210 0.40 4.0 – – – 195 0.40 4.0 – – – – – – – – – T9325 1.6 185 0.40 4.0 110 0.36 4.0 175 0.40 4.0 – – – – – – – – – T9335 1.6 160 0.40 4.0 95 0.36 4.0 – – – – – – – – – – – – TNMG 270612E-RM T7325 1.2 110 0.40 6.0 85 0.36 6.0 – – – – – – – – – – – – T9325 1.2 120 0.40 6.0 70 0.36 6.0 110 0.40 6.0 – – – – – – – – – TNMG 270616E-RM T7325 1.6 115 0.40 6.0 85 0.36 6.0 – – – – – – – – – – – – T9226 1.6 115 0.40 6.0 65 0.36 6.0 105 0.40 6.0 – – – – – – – – – T9315 1.6 135 0.40 6.0 – – – 125 0.40 6.0 – – – – – – – – – T9325 1.6 125 0.40 6.0 75 0.36 6.0 115 0.40 6.0 – – – – – – – – – T9335 1.6 100 0.40 6.0 60 0.36 6.0 – – – – – – – – – – – – TNMG 270624E-RM T7325 2.4 115 0.50 6.0 85 0.45 6.0 – – – – – – – – – – – – T9325 2.4 120 0.50 6.0 70 0.45 6.0 110 0.50 6.0 – – – – – – – – – T9335 2.4 95 0.50 6.0 55 0.45 6.0 – – – – – – – – – – – – TNMG 270632E-RM T9335 3.2 90 0.60 6.0 50 0.54 6.0 – – – – – – – – – – – – TNMG 330924E-RM T9226 2.4 100 0.50 10.0 60 0.45 10.0 95 0.50 10.0 – – – – – – – – – T9335 2.4 90 0.50 10.0 50 0.45 10.0 – – – – – – – – – – – – Позитивная геометрия для чистовой обработки в условиях низкой жесткости без удара. TNMG 160404E-SF H07 0.4 – – – 75 0.14 1.3 120 0.15 1.3 390 0.18 1.3 35 0.12 1.0 – – – T6310 0.4 150 0.15 1.3 105 0.14 1.3 120 0.15 1.3 450 0.18 1.3 45 0.12 1.0 30 0.15 1.0 T7325 0.4 170 0.17 1.3 130 0.15 1.3 – – – – – – 55 0.15 1.0 – – – T7335 0.4 165 0.17 1.3 125 0.15 1.3 – – – – – – 50 0.15 1.0 – – – T8315 0.4 160 0.15 1.3 95 0.14 1.3 150 0.15 1.3 480 0.18 1.3 40 0.12 1.0 30 0.15 1.0 T8330 0.4 150 0.15 1.3 90 0.14 1.3 140 0.15 1.3 450 0.18 1.3 35 0.12 1.0 30 0.15 1.0 T8430 0.4 180 0.15 1.3 95 0.14 1.3 145 0.15 1.3 495 0.18 1.3 35 0.12 1.0 30 0.15 1.0 T9315 0.4 245 0.15 1.3 – – – 230 0.15 1.3 – – – – – – 45 0.15 1.0 T9325 0.4 210 0.17 1.3 125 0.15 1.3 195 0.17 1.3 – – – 45 0.15 1.0 – – – 339

Каталог Dormer Pramet обработка отверстий 2021 - 2022

Каталог Dormer Pramet обработка отверстий 2021 - 2022 Каталог Dormer Pramet фрезерование 2021 - 2022

Каталог Dormer Pramet фрезерование 2021 - 2022 Каталог оснастка Dormer Pramet 2016

Каталог оснастка Dormer Pramet 2016 Общий каталог Dormer Pramet 2017

Общий каталог Dormer Pramet 2017 Каталог Dormer Pramet обработка резьбы 2021 - 2022

Каталог Dormer Pramet обработка резьбы 2021 - 2022