Каталог Dormer Pramet фрезерование 2021 - 2022 - страница 696

Навигация

- MILLING – GENERAL CONTENT

- WORKPIECE MATERIAL GROUPS (WMG)

- CUTTING TOOL PARAMETERS ACCORDING TO ISO 13399

- SOLID HM & HSS MILLS

- CONTENT

- INSTRUCTIONS

- PAGE OVERVIEW

- ICONS OVERVIEW

- SOLID HM MILLS

- TOOL MATERIALS AND SURFACE COATINGS NAVIGATOR

- FAMILIES

- NAVIGATOR

- S2xx

- S216

- S217

- S218

- S219

- S225

- S226

- S227

- S229

- S231

- S233

- S260

- S262

- S264

- S5xx

- S501

- S511

- S521

- S523

- S524

- S525

- S526

- S527

- S529

- S531

- S533

- S534

- S535

- S536

- S561

- S6xx

- S610

- S611

- S612

- S614

- S629

- S637

- S638

- S650

- S654

- S662

- S7xx

- S710

- S713

- S714

- S715

- S716

- S717

- S718

- S722HB

- S739

- S740

- S761

- S763

- S765

- S765HB

- S766

- S767

- S768

- S770HB

- S771HB

- S772HB

- S773HB

- S791

- S8xx

- S802HA

- S802HB

- S803HA

- S803HB

- S804HA

- S804HB

- S812HA

- S812HB

- S813HA

- S813HB

- S814HA

- S814HB

- S822

- S823

- S9xx

- S902

- S903

- S904

- S922

- S933

- S944

- S991

- FEED PER TOOTH TABLE

- CORRECTION FACTORS

- BARREL-SHAPE MILL – FEED PER TOOTH TABLE

- SOLID HSS MILLS

- TOOL MATERIALS NAVIGATOR

- SURFACE TREATMENTS AND COATINGS NAVIGATOR

- NAVIGATOR

- C1xx

- C110

- C122

- C123

- C126

- C135

- C139

- C159

- C167

- C2xx

- C246

- C247

- C273

- C295

- C3xx

- C305

- C306

- C333

- C336

- C346

- C352

- C353

- C367

- C4xx

- C400

- C403

- C407

- C413

- C428

- C492

- C5xx

- C500

- C505

- C7xx

- C700

- C710

- C8xx

- C800

- C801

- C810

- C820

- C822

- C825

- C830

- C831

- C837

- C835

- C9xx

- C907

- C908

- C920

- C922

- C948

- Dxxx

- D200

- D400

- D402

- D420

- D422

- D745

- D747

- D750

- D751

- D753

- D752

- D763

- FEED PER TOOTH TABLE

- CORRECTION FACTORS

- SLITTING SAWS – TOOTH PITCH CHOICE TABLES

- TECHNICAL INFORMATION

- HSS MATERIALS

- HM MATERIALS

- SURFACE TREATMENTS / SURFACE COATINGS

- MILLING TECHNICAL INFO

- OPERATING FORMULAS

- TROUBLESHOOTING

- ROTARY BURRS

- CONTENT

- CARBIDE ROTARY BURRS

- PAGE OVERVIEW

- ICONS OVERVIEW

- TOOL MATERIALS NAVIGATOR

- SURFACE AND TREATMENTS COATINGS NAVIGATOR

- NAVIGATOR

- RECOMMENDED OPERATING SPEED (RPM)

- P1xx

- P100

- P101

- P5xx

- P501

- P505

- P507

- P509

- P511

- P513

- P515

- P521

- P523

- P6xx

- P601

- P605

- P607

- P609

- P611

- P613

- P615

- P621

- P7xx

- P701

- P703

- P705

- P707

- P709

- P711

- P713

- P715

- P721

- P8xx

- P801

- P801C

- P803

- P803C

- P805

- P805C

- P807

- P807C

- P809

- P811

- P811C

- P813

- P813C

- P815

- P815C

- P817

- P819

- P821

- P821C

- P823

- P825

- P831

- P833

- P835

- P837

- P841

- P842

- P843

- P844

- P880

- P890

- GENERAL HINTS

- THREAD MILLS

- CONTENT

- PAGE OVERVIEW

- ICONS OVERVIEW

- TOOL MATERIALS AND SURFACE COATINGS NAVIGATOR

- NAVIGATOR

- J200

- J205

- J210

- J215

- J220

- J225

- J235

- J245

- J260

- J280

- FEED PER TOOTH TABLE

- NUMBER OF PASSES TABLE

- GENERAL HINTS

- INDEXABLE MILLS

- CONTENT

- INSTRUCTIONS

- CUTTERS – PAGE OVERVIEW

- INSERTS – PAGE OVERVIEW

- ICONS OVERVIEW

- PROGRAM OVERVIEW

- GRADES – NAVIGATOR

- GRADES – OVERVIEW

- NAVIGATOR

- FACE MILLING

- SQUARE SHOULDER MILLING

- DEEP SHOULDER MILLING

- SLOT MILLING

- COPY MILLING

- HIGH FEED MILLING

- CHAMFER, T-SLOT MILLING

- ISO CODE DESIGNATION – SHELL MILL BODIES

- ISO CODE DESIGNATION – END SHOULDER MILL BODIES

- ISO CODE DESIGNATION – MILLING INSERTS

- FACE MILLS

- SHN06C

- SHN09C

- SOD05

- SOD06D

- SOE06Z

- SOE09Z

- SSE09

- SSN12Z

- SPN13

- CHN09

- FSB22X

- SQUARE SHOULDER MILLS

- SAD07D

- SAD11E

- SAD16E

- SAP10D

- SAP16D

- STN10

- STN16

- SLN12

- SLN16

- SSO05O

- SSO09

- SSD12

- FTB27X

- DEEP SHOULDER MILLS

- J(T)-SAD11E

- J(T)-SAD16E

- J(T)-SLSN

- J(T)-SSAP

- J(T)-2416

- J(T)-CSD12X

- SLOT MILLS

- S90SN

- S90CN(XN)

- COPY MILLS

- SRC10

- SRC12

- SRC16

- SRC20

- SRD05

- SRD07

- SRD10

- SRD12

- SRD16

- L2-SZP

- K3-CXP

- K2-SRC

- K2-SLC

- K2-PPH

- SVC22C

- SWN04C

- SCN05C

- HIGH FEED MILLS

- SBN10

- SSN11

- SPD09

- SZD07

- SZD09

- SZD12

- CHAMFER & T-SLOTS MILLS

- SSD09

- N-SSO09

- 2516

- 2636

- J(T)-SXP16

- F-SCC

- OTHER MILLING INSERTS

- ADKT 15

- ADKX 15

- APMT 16

- CNM

- ODMT 05

- OFKR 07

- RDET

- RDEX

- RDHX 20

- RPET 12

- RPEW 12

- RPEX

- SEEN

- SEER

- SEET 12

- SEET 12-FA

- SEET 12-PM

- SEEW 12

- SFCN

- SNHF

- SNHN

- SNKX

- SNUN

- SPGN

- SPGN 25 DZ

- SPKN

- SPKR

- SPKX

- SPUN

- TNJF

- TPCN 16

- TPKN

- TPKR

- TPUN

- VCGT 22-FA

- XDHW

- TECHNICAL INFORMATION

- WORKPIECE MATERIAL GROUP (WMG)

- CORRECTION FACTORS

- DEFINITION OF BASIC TERMS

- NOMOGRAM FOR CALCULATING THE WORKING GEOMETRY OF MILLING TOOLS

- CHOICE OF TOOL

- CHOICE OF CUTTING INSERT

- GEOMETRY OF MILLING INSERTS

- A

- ADEX 07-FA

- ADEX 11T308SR-HF ADEX 07-HF

- ADEX 11-FA

- ADEX 11-HF

- ADEX 11-HF2

- ADEX 16-FA

- ADEX 16-FM

- ADEX 16-HF

- ADEX 16-HF2

- ADKT 15-M

- ADKX 15-F

- ADKX 15-F (RAD)

- ADMX 07-F

- ADMX 07-M

- ADMX 11-F

- ADMX 11-M

- ADMX 11-MF

- ADMX 11-MM

- ADMX 11-R

- ADMX 16-F

- ADMX 160616PR-R ADMX 16-M

- ADMX 16-MF

- ADMX 16-MM

- ADMX 16-R

- ANHX 10-F

- APET 15EN

- APET 15SN

- APET 16-FA

- APEW 15ER

- APEW 15SR

- APKT 10-FA

- APKT 10-M

- APKT 16-GM

- APKT 16-HM

- ? APMT 1604PDER-FM APMT 16-F

- APMT 16-FM

- APMT 16 ER-R

- APMT 16 SR-R

- B

- BNGX 10-HM

- BNGX 10-M

- BNGX 10-MM

- C

- CCMX -TS1

- CNHQ 10

- CNHX 05-WM

- CNM 563

- H

- HNEF 09-F

- HNEF 09-M

- HNEF 09-W

- HNGX 06-F

- HNGX 06-M

- HNGX 06-R

- HNGX 09-F

- HNGX 09-FF

- HNGX 09-M

- HNGX 09-R

- HNMF 09-R

- L

- LC 12-CH

- LC 12-RE

- LC -KP

- LC -KPF

- LNET 16-M

- LNET 16-R

- LNG(U)X 12-M

- LNGU 16-FA

- LNGU 16-M

- LNGX 12-F

- LNGX 12-FA

- LNGX 12-MF

- LNGX 12-MM

- LNGX 12-R

- LNMU 16-F

- LNMU 16-M

- LNMU 16-R

- O

- ODEW 06

- ODKT 05-F

- ODK(M)T 05-FM

- ODMT 05-R

- ODMT 06

- ODMX 06

- OEHT 06-FA

- OEHT 06-M

- OEHT 06-MF

- OEHT 06-MM

- OEHT09-M

- OEHT 09-MM

- OFKR 07-M

- P

- PDKT 09-FM

- PDKX 09-FM

- PDMW 09

- ? PNMQ 1308DNSN PDMX 09-M

- PDMX 09-R

- PNMQ 13

- PNMU 13-M

- PPH -CL1

- PPH -CL4

- PPHE -SM1

- PPHF -CE1

- PPHT-A2

- R

- RC

- RC -F

- RCMT -F

- RCMT -M

- RCMT -R

- RCMT SN-R

- RCMT 12EN-R

- RDET

- RDEW

- RDEX 12

- RDEX 16

- RDGT 07

- RDGT 10

- RDGT 12

- RDGT 12-F

- RDGT 12-FM

- RDHT -FA

- RDHX 05

- RDHX MOT

- RDMT

- RDMT 12

- RDMT -R

- RDMX

- REHT -M

- REHT -MM

- RPET 12

- RPET 15-M

- RPEW 12

- RPEW 15

- RPEX -12

- S

- SBKX 22

- SBMR 22

- SBMR 22-R

- SDEW 09EN

- SDEW 09SN

- SDEX 09-74

- SDGX 12-FM

- SDKT 12-F (IM)

- SDMT 12-F

- SDMT 12-F (IM)

- SDK(M)T 12-FM (IM)

- SDMT 12-R (IM)

- SDMT 12-M

- SDMT 12-R

- SDMX 12-M

- SEEN 12FN

- SEEN SN

- SEER EN

- SEER SN

- SEET 09

- SEET 12EN

- SEET 12SN

- SEET 12-FA

- SEET 12-PM

- SEEW 12 EN

- SEEW 12 SN

- SEMT 09

- SFCN 12

- SNET 13-M

- SNGX 11-M

- SNGX 11-MM

- SNGX 13-M

- SNGX 13-R

- SNHF -M

- SNHN

- SNHQ 11

- SNHQ 12TN

- SNHQ 12EN

- SNHQ 12TRL

- SNK(M)T 12-M

- SNKX

- SNMT 12-R

- SNUN

- SOMT 05-M

- SOMT 09-M

- SOMT 09-MI

- SOMT 09-P

- SPET 12EN

- SPET 12S

- SPEW 12EN

- SPEW 12SN

- SPGN

- SPGN DZ

- SPKN EDSR(L)

- SPKN EDER(L)

- SPKR

- SPKX

- SPUN

- SPUN 25

- T

- TBMR 27

- TCMT 16-FM

- TNGX 10-F

- TNGX 10-FA

- TNGX 10-M

- TNGX 16-F

- TNGX 16-FA

- TNGX 16-M

- TNJF 12

- TPCN 16

- TPKN ER

- TPKN SR

- TPKR

- TPUN

- V

- VCGT 22-FA

- W

- WNHX 04-WM

- X

- XDHW EN

- XDHW SN

- XEHT

- XNGX ANSN

- XNGX 13

- XNHQ TN

- XP ER-FM

- XPHT 16E

- XPHT 16-FA

- XPHT 16S

- Z

- ZDCW 07

- ZDCW 09

- ZDEW 12

- ZP ER-F

- ZP ER-FM

- ZP ER-M

- ZP ER-R

- MILLING GRADES – OVERVIEW

- WORKING CONDITION WHEN MILLING

- MACHINED SURFACE ROUGHNESS

- TECHNOLOGIES

- TYPES OF WEAR ON MILLING INSERTS

- FORMULAS

- RECOMMENDED TORQUE OF CLAMPING SCREWS

- TECHNICAL INFORMATION ON INSERT BOX

- HARDNESS CONVERSION TABLE

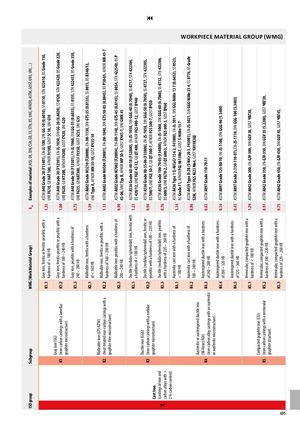

695 WORKPIECE MATERIAL GROUP (WMG) 9 ISO group Subgroup WMG (Work Material Group) kvG Examples of material (AISI, EN, DIN, ČSN, GB, SS, STN, BS, UNE, AFNOR, ASTM, GOST, UNS, UNI, ...) K1.1 Gray iron, ferritic or ferritic-pearlitic with ahardness of < 180 HB1.35ASTM A48 Grade 20 (F11401), EN-JL-100, DIN GG-10 (0.6010), SS 0110, STN 422410, BS Grade 150,UNE FG10, GB HAT 100, AFNOR Ft10D, GOST SC 10, UNI G10 Gray iron (GG)K1(iron-carbon castings with a lamellargraphite microstructure)K1.2Gray iron, ferritic-pearlitic or pearlitic with ahardness of 180 – 240 HB1.00ASTM A48 Grade 30 (F12101), EN-JL-1030, DIN GG-20 (0.6020), SS 0120, STN 422420, BS Grade 220,UNE FG20, GB HT200, AFNOR Ft20D, GOST СЧ20, UNI G20 K1.3 Gray iron, pearlitic with a hardness of240 – 280 HB 0.75 ASTM A48 Grade 50 (F13501), EN-JL-1060, DIN GG-35 (0.6035), SS 0135, STN 422435, BS Grade 350,UNE FG35, GB HAT300, AFNOR Ft35D, GOST SC35, UNI G35 K2.1 Malleable iron, ferritic with a hardnessof < 160 HB 1.39 ASTM A602 Grade M3210 (F20000), EN-JM-1130, DIN GTS-35 (0.8135), SS 0815, BS B340/12,UNE Type A, AFNOR MN 35-10, GOST КЧ35-10 Malleable iron (GTS/GTW)K2(heat-treated iron-carbon castings with agraphite-free microstructure)K2.2Malleable iron, ferritic or pearlitic with ahardness of 160 – 200 HB1.13ASTM A602 Grade M4504 (F20001), EN-JM-1040, DIN GTS-50-05 (0.8045), BS P50-05, AFNOR MB 45-7 K2.3 Malleable iron, pearlitic with a hardness of200 – 240 HB0.90ASTM A602 Grade M7002 (F20004), EN-JM-1140, DIN GTS-45 (0.8145), SS 0854, STN 422540, BS P45-06, UNE Typ B, AFNOR MP 50-5, GOST КЧ45-7, UNI GMN 45 K3.1 Ductile (nodular/spheriodal) iron, ferritic witha hardness of < 180 HB1.23ASTM A536 Grade 60-40-18 (F32800), EN-JS-1030, DIN GGG-40 (0.7040), SS 0717, STN 422304,BS 420/12, UNE FGE 42-12, GB QT 400, AFNOR FGS 400-12, GOST ВЧ40 Cast Iron Ductile iron (GGG)K3(iron-carbon castings with a nodulargraphite microsturcture)K3.2Ductile (nodular/spheriodal) iron, ferritic orpearlitic with a hardness of 180 – 220 HB0.94ASTM A536 Grade 80-55-06 (F33800), EN-JS-1050, DIN GGG-50 (0.7050), SS 0727, STN 422305,BS 500/7, UNE FGE 50-7, GB QT 500-7, AFNOR FGS 500-7, GOST ВЧ50 K (castings of iron andcarbon alloys with > K3.3 Ductile (nodular/spheriodal) iron, pearliticwith a hardness of 220 – 260 HB0.76ASTM A536 Grade 100-70-03 (F34800), EN-JS-1060, DIN GGG-60 (0.7060), SS 0732, STN 422306,BS 600/3, UNE FG70-2, GB QT 600-3, AFNOR FGS 600-3, GOST ВЧ60 2 % carbon content) K4.1 Austenitic cast iron with a hardness of< 180 HB 1.14 ASTM A436 Type 1 (L-NiCuCr 15 6 2, F41000), EN-JL-3011, DIN GGL-NiMn 13 7 (0.6652), SS 0523,BS Grade F1, AFNOR FGL-Ni13Mn7, GOST S-NiMn 13 7 K4.2 Austenitic cast iron with a hardness of180 – 240 HB 0.86 ASTM A439 Type D-2B (S-NiCr 20 3, F43001), EN-JS-3021, DIN GGG-NiMn 23 4, SS 0776, BS GradeS2M, AFNOR FGS Ni23 Mn4, GOST ЧН19Х3Ш Austenitic or austempered ductile iron K4 (Ni-Resist/ADI)(iron-carbon alloy castings with an austeniticK4.3Austempered ductile iron with a hardnessof 240 – 280 HB0.63ASTM A897 Grade 110-70-11 or ausferrite microstructure) K4.4 Austempered ductile iron with a hardnessof 280 – 320 HB0.54ASTM A897 Grade 125-80-10, EN-JS-1100, DIN GGG-90 (5.3400) K4.5 Austempered ductile iron with a hardnessof 320 – 360 HB0.45ASTM A897 Grade 2 (150-110-07), EN-JS-1110, DIN GGG-100 (5.3403) K5.1 Vermicular, compacted graphite iron with ahardness of < 180 HB1.29ASTM A842 Grade 300, EN-GJV-300, DIN GGV 30, GOST ЧВГ30, Compacted graphite iron (CGI)K5(iron-carbon castings with a vermiculargraphite structure)K5.2Vermicular, compacted graphite iron with ahardness of 180 – 220 HB0.97ASTM A842 Grade 350, EN-GJV-350, DIN GGV 35 (5.2200), GOST ЧВГ30, K5.3 Vermicular, compacted graphite iron with ahardness of 220 – 260 HB0.75ASTM A842 Grade 450, EN-GJV-450, DIN GGV 45, GOST ЧВГ45,

Каталог оснастка Dormer Pramet 2016

Каталог оснастка Dormer Pramet 2016 Каталог Dormer Pramet обработка резьбы 2021 - 2022

Каталог Dormer Pramet обработка резьбы 2021 - 2022 Общий каталог Dormer Pramet 2016

Общий каталог Dormer Pramet 2016 Общий каталог Dormer Pramet 2018

Общий каталог Dormer Pramet 2018 Брошюра Dormer Pramet новинки 2021

Брошюра Dormer Pramet новинки 2021 Общий каталог Dormer Pramet 2017

Общий каталог Dormer Pramet 2017