Брошюра Dormer Pramet новинки 2021 - страница 56

Навигация

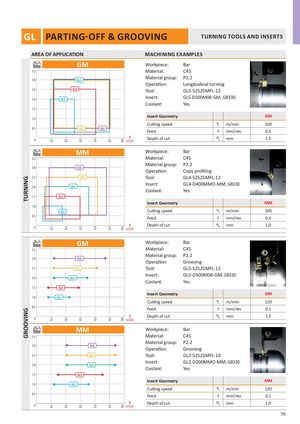

TURNINGGROOVING 0,10,10,10,1 0,20,20,20,2 0,30,30,30,3 0,40,40,40,4 0,50,50,50,5 0,60,60,60,6 GL PARTING-OFF & GROOVING TURNING TOOLS AND INSERTS AREA OF APPLICATION MACHINING EXAMPLES ap GM Workpiece: Bar 3,5 Material: C45 3,0 GL4 Material group: P2.2 Operation: Longitudinal turning 2,5 GL3 Tool: GL5-S2525MFL-12 2,0 GL2 Insert: GL5-D500M08-GM; G8330 Coolant: Yes 1,5 1,0 Insert Geometry GM Cutting speed vc m/min 100 0,5 GL5 GL6 Feed f mm/rev 0,5 0 f Depth of cut ap mm 1,5 ap MM Workpiece: Bar 3,5 Material: C45 Material group: P2.2 3,0 GL6 Operation: Copy profiling 2,5 GL5 Tool: GL4-S2525MFL-12 2,0 GL4 Insert: GL4-D400MMO-MM; G8330 Coolant: Yes 1,5 GL3 Insert Geometry MM 1,0 GL2 Cutting speed vc m/min 100 0,5 Feed f mm/rev 0,4 0 f Depth of cut ap mm 1,0 ap GM Workpiece: Bar 3,5 Material: C45 Material group: P2.2 3,0 GL6 Operation: Grooving 2,5 GL5 Tool: GL5-S2525MFL-12 2,0 GL4 Insert: GL5-D500M08-GM; G8330 Coolant: Yes 1,5 GL3 Insert Geometry GM 1,0 GL2 Cutting speed vc m/min 120 0,5 Feed f mm/rev 0,1 0 f Depth of cut ap mm 1,5 ap MM Workpiece: Bar 3,5 Material: C45 Material group: P2.2 3,0 GL6 Operation: Grooving 2,5 GL5 Tool: GL2-S2525MFL-10 2,0 Insert: GL2-D200MMO-MM; G8330GL4 Coolant: Yes 1,5 GL3 Insert Geometry MM 1,0 GL2 Cutting speed vc m/min 120 0,5 Feed f mm/rev 0,1 0 f Depth of cut ap mm 1,0 55

Общий каталог Dormer Pramet 2016

Общий каталог Dormer Pramet 2016 Каталог Dormer Pramet обработка отверстий 2021 - 2022

Каталог Dormer Pramet обработка отверстий 2021 - 2022 Каталог Dormer Pramet фрезерование 2021 - 2022

Каталог Dormer Pramet фрезерование 2021 - 2022 Общий каталог Dormer Pramet 2017

Общий каталог Dormer Pramet 2017 Каталог оснастка Dormer Pramet 2016

Каталог оснастка Dormer Pramet 2016 Каталог Dormer Pramet обработка резьбы 2021 - 2022

Каталог Dormer Pramet обработка резьбы 2021 - 2022