Брошюра Dormer Pramet новинки 2021 - страница 3

Навигация

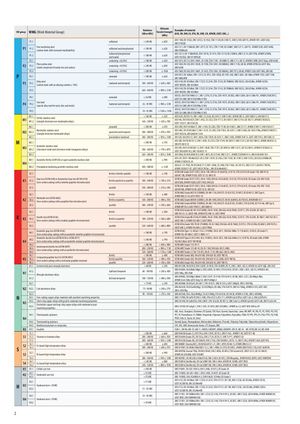

ISO group WMG (Work Material Group) Hardness(HB or HRC)UltimateTensile Strength(MPa)Examples of material(AISI, EN, DIN, SS, STN, BS, UNE, CN, AFNOR, GOST, UNI...) P1.1 sulfurized < 240 HB ≤ 830 AISI 1108, EN 15S22, DIN 1.0723, SS 1922, ČSN 11120, BS 210A15, UNE F.210F, GB Y15, AFNOR 10F1, GOST A30,UNI CF10S20 P1 P1.2 Free machining steel(carbon steels with increased machinability) sulfurized and phosphorized < 180 HB ≤ 620 AISI 1211, EN 11SMn30, DIN 1.0715, SS 1912, ČSN 11109, BS 230M7, UNE F.2111, GB Y15, AFNOR S250, GOST A40G,UNI CF9SMn28 P1.3 sulfurized/phosphorizedand leaded < 180 HB ≤ 620 AISI 12L13, EN 11SMnPb30, DIN 1.0718, SS 1914, ČSN 12110, BS 210M16, UNE F.2114, GB Y15Pb, AFNOR S250Pb,GOST AS35G2, UNI CF10SPb20 P2.1 containing <0.25%C < 180 HB ≤ 620 AISI 1015, EN C15, DIN 1.0401, SS 1350, ČSN 11301 , BS 080A15, UNE F.111, GB 15, AFNOR C18RR, GOST St2ps, UNI Fe360 P2 P2.2 Plain carbon steel(steels comprised of mainly iron and carbon) containing <0.55%C < 240 HB ≤ 830 AISI 1030, EN C30, DIN 1.0528, SS 1550, ČSN 12031, BS 080M32, UNE F.1130, GB 30, AFNOR AF50C30, GOST 30G,UNI Fe590 P2.3 containing >0.55%C < 300 HB ≤ 1030 AISI 1060, EN C60, DIN 1.0601, SS 1655, ČSN 12061, BS 080A62, UNE F513, GB 60, AFNOR 1C60, GOST 60G, UNI C60 P P3.1 annealed < 180 HB ≤ 620 AISI 5015, EN 16Mo3, DIN 1.5415, SS 2912, ČSN 15020, BS 1501-240, UNE F.2601, GB 16Mo, AFNOR 15D3, GOST 15M,UNI 16Mo3KW P3 P3.2 Alloy steel(carbon steels with an alloying content ≤ 10%) hardened and tempered 180 - 260 HB > 620 ≤ 900 AISI 4140, EN 42CrMo4, DIN 1.7225, SS 2244, ČSN 15142, BS 708M40, UNE F.8232, GB 42CrMo, AFNOR 42CD4,GOST 40ChFA, UNI 42CrMo4 P3.3 260 - 360 HB > 900 ≤ 1240 AISI 4140, EN 42CrMo4, DIN 1.7225, SS 2244, ČSN 15142, BS 708M40, UNE F.8232, GB 42CrMo, AFNOR 42CD4,GOST 40ChFA, UNI 42CrMo4 P4.1 annealed < 26 HRC ≤ 900 AISI D2, EN X155CrVMo12-1, DIN 1.2370, SS 2736, ČSN 19573, BS BD2, UNE F.520A, GB Cr12Mo1V1, AFNOR Z160CDV12,GOST Ch12MF, UNI X155CrVMo121KU P4 P4.2 Tool steel(special alloy steel for tools, dies and molds) hardened and tempered 26 - 39 HRC > 900 ≤ 1240 AISI D2, EN X155CrVMo12-1, DIN 1.2370, SS 2736, ČSN 19573, BS BD2, UNE F.520A, GB Cr12Mo1V1, AFNOR Z160CDV12,GOST Ch12MF, UNI X155CrVMo121KU P4.3 39 - 45 HRC > 1240 ≤ 1450 AISI D2, EN X155CrVMo12-1, DIN 1.2370, SS 2736, ČSN 19573, BS BD2, UNE F.520A, GB Cr12Mo1V1, AFNOR Z160CDV12,GOST Ch12MF, UNI X155CrVMo121KU M1 M1.1M1.2Ferritic stainless steel(straight chromium non-hardenable alloys) < 160 HB ≤ 520 AISI S429, EN X7Cr14, DIN 1.4001, SS 2326, BS 434S17, UNE F.3401, AFNOR Z8C12, GOST 08Ch13, UNI X6CrTi12160 - 220 HB> 520 ≤ 700AISI 446, EN X10CrAl24, DIN 1.4762, SS 2322, ČSN 17113, BS 430S17, UNE F.3154, GB 10Cr17, AFNOR Z10CAS24,GOST 12Ch17, UNI X16Cr26 M2.1 annealed < 200 HB ≤ 670 AISI 430F, EN X14CrMoS17, DIN 1.4104, SS 2383, ČSN 17140, BS 410S21, UNE F.3117, AFNOR Z10CF17, UNI X10CrS17 M2 M2.2 Martensitic stainless steel(straight chromium hardenable alloys) quenched and tempered 200 - 280 HB > 670 ≤ 950 AISI 440C, EN X105CrMo17, DIN 1.4125, SS 2385, ČSN 17023, BS 425C11, UNE F.3402; GB 102Cr17Mo, AFNOR Z100CD17,GOST 95Ch18, UNI GX6CrNi 13 04 M2.3 precipitation-hardened 280 - 380 HB > 950 ≤ 1300 AISI 420, EN X45Cr13, DIN 1.4034, ČSN 17029, BS 425C11, UNE F.3405, AFNOR Z44C14, GOST 20X17H12, UNI X30Cr13 M M3.1 < 200 HB ≤ 750 AISI 308, EN X5CrNi18-12, DIN 1.4303, SS 2352, ČSN 17249, BS 305S17, UNE F.3513, GB 10Cr18Ni12, AFNOR Z8CN18.12,UNI X7CrNi18 10 M3 M3.2 Austenitic stainless steel(chromium-nickel and chromium-nickel-manganese alloys) 200 - 260 HB > 750 ≤ 870 AISI 309, EN X15CrNiSi20-12, DIN 1.4828, ČSN 17251, BS 309S24, UNE F.3312, GB 1Cr23Ni13, AFNOR Z15CNS20.12,GOST 20Ch20N14S2, UNI 16CrNi23 14 M3.3 260 - 300 HB > 870 ≤ 1040 AISI 5848, EN X45CrNiW18-9, DIN 1.4873, BS 331S40, UNE F.3211, AFNOR Z35CNWS14-4, UNI X45CrNiW 18 9 M4.1 Austenitic-ferritic (DUPLEX) or super-austenitic stainless steelM4M4.2Precipitation hardening austenitic stainless steel < 300 HB ≤ 990 AISI 329, EN X1-NiCrMoCU25-20-5, DIN 1.4539, SS 2562, ČSN 17265, BS 318S13, UNE F.3552, GB 022Cr25NiMo2N,AFNOR Z1NCDU25.20300 - 380 HB≤ 1320AISI 631 (17-7PH), EN X7CrNiAL17-7, DIN 1.4568, SS 2388, ČSN 17465 , BS 301S13, UNE F.3217, GB 07Cr17Ni7Al,AFNOR 29CNA17-07, GOST 09Ch17N7Ju1, UNI X53CrMnNiN21 K1.1 ferritic or ferritic-pearlitic < 180 HB ≤ 190 ASTM A48 Grade 20 (F11401), EN-JL-100, DIN GG-10 (0.6010), SS 0110, STN 422410, BS Grade 150, UNE FG10,GB HAT 100, AFNOR Ft10D, GOST SC 10, UNI G10 K1 K1.2 Gray iron (ASTM A48) or Automotive Gray iron (ASTM A159)(iron-carbon castings with a lamellar graphite microstructure)ferritic-pearlictic or pearlitic180 - 240 HB> 190 ≤ 310ASTM A48 Grade 30 (F12101), EN-JL-1030, DIN GG-20 (0.6020), SS 0120, STN 422420, BS Grade 220, UNE FG20,GB HT200, AFNOR Ft20D, GOST СЧ20, UNI G20 K1.3 pearlitic 240 - 280 HB > 310 ≤ 390 ASTM A48 Grade 50 (F13501), EN-JL-1060, DIN GG-35 (0.6035), SS 0135, STN 422435, BS Grade 350, UNE FG35,GB HAT300, AFNOR Ft35D, GOST SC35, UNI G35 K2.1 ferritic < 160 HB ≤ 400 ASTM A602 Grade M3210 (F20000), EN-JM-1130, DIN GTS-35 (0.8135), SS 0815, BS B340/12, UNE Type A,AFNOR MN 35‑10, GOST КЧ35-10 K2 K2.2 Malleable iron (ASTM A602)(iron-carbon castings with a graphite-free microstructure)K2.3ferritic or pearlitic 160 - 200 HB > 400 ≤ 550 ASTM A602 Grade M4504 (F20001), EN-JM-1040, DIN GTS-50-05 (0.8045), BS P50-05, AFNOR MB 45-7pearlitic200 - 240 HB> 550 ≤ 660ASTM A602 Grade M7002 (F20004), EN-JM-1140, DIN GTS-45 (0.8145), SS 0854, STN 422540, BS P 45-06, UNE Typ B,AFNOR MP 50-5, GOST КЧ45-7, UNI GMN 45 K3.1 ferritic < 180 HB ≤ 560 ASTM A536 Grade 60-40-18 (F32800), EN-JS-1030, DIN GGG-40 (0.7040), SS 0717, STN 422304, BS 420/12,UNE FGE 42‑12, GB QT 400, AFNOR FGS 400-12, GOST ВЧ40 K K3 K3.2 Ductile iron (ASTM A536)(iron-carbon castings with a nodular graphite microsturcture)ferritic or pearlitic 180 - 220 HB > 560 ≤ 680 ASTM A536 Grade 80-55-06 (F33800), EN-JS-1050, DIN GGG-50 (0.7050), SS 0727, STN 422305, BS 500/7, UNE FGE 50-7,GB QT 500-7, AFNOR FGS 500-7, GOST ВЧ50 K3.3 pearlitic 220 - 260 HB > 680 ≤ 800 ASTM A536 Grade 100-70-03 (F34800), EN-JS-1060, DIN GGG-60 (0.7060), SS 0732, STN 422306, BS 600/3, UNE FG70-2,GB QT 600-3, AFNOR FGS 600-3, GOST ВЧ60 K4.1 Austenitic gray iron (ASTM A436)(iron-carbon alloy castings with an austenitic lamellar graphite microstructure) < 180 HB ≤ 190 ASTM A436 Type 1 (L-NiCuCr 15 6 2, F41000), EN-JL-3011, DIN GGL-NiMn 13 7 (0.6652), SS 0523, BS Grade F1,AFNOR FGL-Ni13Mn7, GOST S-NiMn 13 7 K4 K4.2 Austenitic ductile iron (ASTM A439 or ASTM A571)(iron-carbon alloy castings with an austenitic nodular graphite microstructure)< 240 HB ≤ 740 ASTM A439 Type D-2B (S-NiCr 20 3, F43001), EN-JS-3021, DIN GGG-NiMn 23 4, SS 0776, BS Grade S2M, AFNORFGS Ni23 Mn4, GOST ЧН19Х3Ш K4.3 < 280 HB > 840 ≤ 980 ASTM A897 Grade 110-70-11 K4.4K4.5Austempered ductile iron (ASTM A897)(iron-carbon alloy castings with an ausferrite microstructure) 280 - 320 HB > 980 ≤ 1130 ASTM A897 Grade 125-80-10, EN-JS-1100, DIN GGG-90 (5.3400)320 - 360 HB> 1130 ≤ 1280ASTM A897 Grade 2 (150-110-07), EN-JS-1110, DIN GGG-100 (5.3403) K5 K5.1K5.2K5.3Compacted graphite iron CGI (ASTM A842)(iron-carbon castings with a vermicular graphite structure)ferritic < 180 HB ≤ 400 ASTM A842 Grade 300, EN-GJV-300, DIN GGV 30, GOST ЧВГ30,ferritic-pearlitic180 - 220 HB> 400 ≤ 450ASTM A842 Grade 350, EN-GJV-350, DIN GGV 35 (5.2200), GOST ЧВГ30,pearlitic220 - 260 HB> 450 ≤ 500ASTM A842 Grade 450, EN-GJV-450, DIN GGV 45, GOST ЧВГ45, N1.1 Commercially pure wrought aluminum < 60 HB ≤ 240 UNS A91200, EN AL99.0, DIN 3.0205, SS 4010, STN 424009, BS 1C, UNE L-3001, GB L5, AFNOR A4, GOST АДС, UNI 3567 N1 N1.2 Wrought aluminum alloysN1.3 half hard tempered 60 - 100 HB > 240 ≤ 400 UNS A93004, EN AlMn0.5Mg0.5, DIN 3.0505, SS 4054, STN 424432, BS N31, UNE L-3831, GB LF2, AFNOR A-M1,GOST АМц, UNI 3568full hard tempered100 - 150 HB> 400 ≤ 590UNS A95083, EN AlMg4.5Mn0.7, DIN 3.3547, SS 4140, STN 424415, BS N8, UNE L-3321, GB AlMg4.5Mn,AFNOR A-G4.5Mn, GOST Amg 4.5, UNI P-AlMg4.4 N2.1 < 75 HB ≤ 240 UNS A02080, EN AlCu4S, BS LM11, STN 424331, UNE Al Si1Cu, GOST AMg5K, UNI G-AlSi7Mg N2 N2.2 Cast aluminium alloys 75 - 90 HB > 240 ≤ 270 UNS A02420, EN AlCu4Ni2Mg2, SS AlSi7MgFe, BS LM6, STN 424519, UNE Al-7SiMg, AFNOR A-S7G, GOST AK7,UNI G-AlSi7Mg N2.3 90 - 140 HB > 270 ≤ 440 UNS A03360, EN G-ALCu4NiMg2, SS ALSi10Mg, STN 424336, BS LM 30, AFNOR A-S10G, UNI G-AlSi9Mg N N3.1 Free-cutting copper-alloys materials with excellent machining properties UNS C14700, EN CuPb1P, DIN 2.1498, STN 423214, BS C111, AFNOR CuZn35Pb2, GOST L63-3, UNI CuS(P0.01) N3 N3.2N3.3Short-chip copper-alloys with good to moderate machining propertiesElectrolytic copper and long-chip copper-alloys with moderate to poormachining propertiesUNS C81540, EN CuNi2SiCr, DIN 2.0857, STN 423220, BS NS113, UNE CuSn12, AFNOR CuZn40, GOST L60, UNI P-CuZn-40UNS C10100, EN CuAg0.1, DIN 2.1203, SS 5010, UNE CUSi3Mn1, AFNOR Cu-C2, GOST M1f, UNI Cu-OF ABS, Acryl, Duraplast, Elastomer, EP, Epoxid, FEP, Fluor, Gummi, Kautschuk, Latex, MF, MPF, PA, PAI, PC, PE, PEEK, PEI, PES, N4.1 Thermoplastic polymers PET, PF, Phenolharze, PI, PMMA, Polyamide, Polyester, Polyolefine, Polysulfon, POM, PP, PPE, PPS, PS, PSU, PTFE, PU, PUR, N4 PVDF, SAN, SI, Styrol, UF, Ureol N4.2 Thermosetting polymers Aramid, Epoxy, Fluoropolymer, Mehacrylate, Melamine, Phenolic, Polyester, Polyimide, Polymethacrylimide, Polyurethane N4.3 Reinforced polymers or composites CFK, GFK, GMT, Honeycomb, Kevlar, LFT, Organo, SMC N5 N5.1 Graphite CGM-1, CM-00, GM-10, GM-11, GR030, GR030PI, GR060, GR060PI, GR125, MC-01, MC-01RO, MC-03, MC-03M S1.1 < 200 HB ≤ 660 UNS R50250 (Grade 1), EN Ti 99.6, DIN 3.7035, BS TA.2, UNE Ti-Po2, AFNOR T-40, GOST BT1-00 S1 S1.2 Titanium or titanium alloys 200 - 280 HB > 660 ≤ 950 UNS R56404 (Grade 29), EN Ti2Cu, DIN 3.7124, BS TA.21, UNE Ti-P11, AFNOR T-U2 S1.3 280 - 360 HB > 950 ≤ 1200 UNS R54250 (Grade 38), EN TiAl6V4, DIN 3.7165, ČSN TiAl6VELI, BS TA. 13, UNE Ti-P63, AFNOR T-A6V, GOST BT6 S S2 S2.1S2.2Fe-based high-temperature alloysS3S3.1Ni-based high-temperature alloys < 200 HB ≤ 690 UNS N08801 (Incoloy 801), EN X8 NiCrAlTi31-21, DIN 1.4959, BS NA 15, AFNOR Z8NC33-21200 - 280 HB> 690 ≤ 970UNS N19907, EN X6NiCrTiMoVB25-15-2, DIN 1.4980, SS 2570, BS HR52, AFNOR Z6NCTDV25.15B, GOST 36НХТЮ< 280 HB≤ 940UNS A09706 (Inconel 706), EN NiCr25FeAl, DIN 2.4856, BS HR 6, ČSN Inconel 625, UNE F.3313, GB 1Cr16Ni35,AFNOR NC22FeDNB, GOST XH38BT S3.2 280 - 360 HB > 940 ≤ 1200 UNS N07001, EN NiCr20Co13Mo4Ti3Al, DIN 2.4654, BS HR 2, ČSN Waspaloy, AFNOR NCKD 20ATV, GOST ХН80ТБЮ S4 S4.1S4.2Co-based high-temperature alloys < 240 HB ≤ 800 UNS R30016 (Stellite 6b), EN CoCr20W15Ni, DIN 2.4964, AFNOR KC 20 WN, GOST ЛК52240 - 320 HB> 800 ≤ 1070UNS R30016 (Stellite 6b), EN CoCr20W15Ni, DIN 2.4964, AFNOR KC 20 WN, GOST ЛК52 H1 H1.1 Chilled cast iron < 440 HB UNS F45001, EN-GJS-1050-6, DIN 5.3406, SS 0512, BS Grade 2A H2 H2.1H2.2Hardended cast iron < 55 HRC UNS F45003, EN-GJS-1400-1, DIN 5.3405, SS 0457, BS Grade 3D> 55 HRCUNS F45003, EN G-X260NiCr4-2, DIN 0.9620, SS 0466, BS Grade S H3.1HH3H3.2Hardened steel <55HRC < 51 HRC AISI 4135, EN 34CrMo4, DIN 1.7220, SS 2234, STN 415131, BS 198, UNE F.1250, GB 35CrMo, AFNOR 35CD4,GOST АС38ХГМ, UNI 35CrMo4KB51 - 55 HRCAISI 4135, EN 34CrMo4, DIN 1.7220, SS 2234, STN 415131, BS 198, UNE F.1250, GB 35CrMo, AFNOR 35CD4,GOST АС38ХГМ, UNI 35CrMo4KB H4.1H4Hardened steel >55HRCH4.2 55 - 59 HRC UNS T31501, EN 100MnCrW4, DIN 1.2510, SS 2140, STN 419413, BS BO1, UNE F.5220, GB 9CrWMn, AFNOR 90MWCrV5,GOST 9ХВГ, UNI 95MNWCr5KU> 59 HRCUNS T31501, EN 100MnCrW4, DIN 1.2510, SS 2140, STN 419413, BS BO1, UNE F.5220, GB 9CrWMn, AFNOR 90MWCrV5,GOST 9ХВГ, UNI 95MNWCr5KU 2

Общий каталог Dormer Pramet 2016

Общий каталог Dormer Pramet 2016 Каталог Dormer Pramet обработка отверстий 2021 - 2022

Каталог Dormer Pramet обработка отверстий 2021 - 2022 Каталог Dormer Pramet фрезерование 2021 - 2022

Каталог Dormer Pramet фрезерование 2021 - 2022 Общий каталог Dormer Pramet 2017

Общий каталог Dormer Pramet 2017 Каталог оснастка Dormer Pramet 2016

Каталог оснастка Dormer Pramet 2016 Каталог Dormer Pramet обработка резьбы 2021 - 2022

Каталог Dormer Pramet обработка резьбы 2021 - 2022