Общий каталог Dijet 2018 - страница 83

Навигация

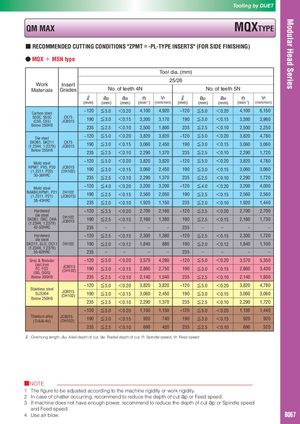

Tooling by DIJET QM MAX MQXTYPE ■ RECOMMENDED CUTTING CONDITIONS "ZPMT*-PL-TYPE INSERTS" (FOR SIDE FINISHING) ● MQX + MSN type Tool dia. (mm) 25/26 Work Insert Materials Grades No. of teeth 4N No. of teeth 5N ℓ ap ae n Vf ℓ ap ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) Carbon steel ~120 ≦5.0 <0.20 4,100 4,920 ~120 ≦5.0 <0.20 4,100 6,150 S50C, S55C CX75(C50, C55)JC8015190≦3.0<0.15 3,300 3,170 190 ≦3.0 <0.15 3,300 3,960 Below 250HB 235 ≦2.5 <0.10 2,500 1,800 235 ≦2.5 <0.10 2,500 2,250 Die steel ~120 ≦5.0 <0.20 3,820 3,820 ~120 ≦5.0 <0.20 3,820 4,780 SKD61, SKD11 CX75(1.2344, 1.2379)JC8015190≦3.0<0.153,060 2,450 190 ≦3.0 <0.15 3,060 3,060 Below 255HB 235 ≦2.5 <0.10 2,290 1,370 235 ≦2.5 <0.10 2,290 1,720 Mold steel ~120 ≦5.0 <0.20 3,820 3,820 ~120 ≦5.0 <0.20 3,820 4,780 HPM7, PX5, P20 JC8015(1.2311, P20)(DH102)190≦3.0<0.153,060 2,450 190 ≦3.0 <0.15 3,060 3,060 30-36HRC 235 ≦2.5 <0.10 2,290 1,370 235 ≦2.5 <0.10 2,290 1,720 Mold steel ~120 ≦4.0 <0.20 3,200 3,200 ~120 ≦4.0 <0.20 3,200 4,000 NAK80,HPM1, P21 DH102(1.2311, P21)(JC8015)190≦2.5<0.152,560 2,050 190 ≦2.5 <0.15 2,560 2,560 38-43HRC 235 ≦2.0 <0.10 1,920 1,150 235 ≦2.0 <0.10 1,920 1,440 Hardened ~120 ≦3.5 <0.20 2,700 2,160 ~120 ≦3.5 <0.20 2,700 2,700 die steelSKD61, DAC, DHA(1.2344, 1.2379)DH102JC8015190≦2.5<0.152,1601,380 190 ≦2.5 <0.15 2,160 1,730 42-52HRC 235 – – – – 235 – – – – Hardened ~120 ≦2.5 <0.15 2,300 1,380 ~120 ≦2.5 <0.15 2,300 1,720 die steel SKD11, SLD, DC11 DH102 190 ≦2.0 <0.12 1,840 880 190 ≦2.0 <0.12 1,840 1,100 (1.2344, 1.2379) 55-62HRC 235 – – – – 235 – – – – Grey & Nodular ~120 ≦5.0 <0.20 3,570 4,280 ~120 ≦5.0 <0.20 3,570 5,350 cast ironFC, FCD(GG, GGG)JC8015(DH102)190≦3.0<0.15 2,860 2,750 190 ≦3.0 <0.15 2,860 3,430 Below 300HB 235 ≦2.5 <0.10 2,140 1,540 235 ≦2.5 <0.10 2,140 1,930 ~120 ≦5.0 <0.20 3,820 3,820 ~120 ≦5.0 <0.20 3,820 4,780 Stainless steelSUS304Below 250HBJC8015(DH102)190≦3.0<0.153,060 2,450235≦2.5<0.102,2901,370190≦3.0 <0.15 3,060 3,060235≦2.5<0.102,2901,720 ~120 ≦5.0 <0.20 1,150 1,150 ~120 ≦5.0 <0.20 1,150 1,440 Titanium alloy JC8015(Ti-6Al-4V)(DH102)190≦3.0<0.15 920 740 190 ≦3.0 <0.15 920 920 235 ≦2.5 <0.10 690 420 235 ≦2.5 <0.10 690 520 ℓ: Overhung length, ap: Axial depth of cut, ae: Radial depth of cut, n: Spindle speed, Vf: Feed speed ■NOTE 1 The figure to be adjusted according to the machine rigidity or work rigidity. 2 In case of chatter occurring, recommend to reduce the depth of cut ap or Feed speed. 3 If machine does not have enough power, recommend to reduce the depth of cut ap or Spindle speed and Feed speed. 4 Use air blow. B067

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском