Общий каталог Dijet 2018 - страница 66

Навигация

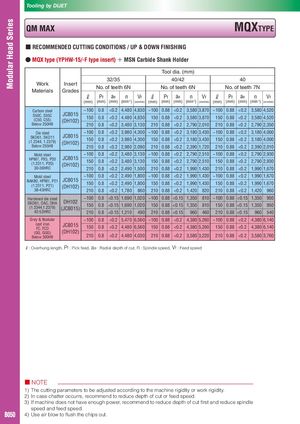

Tooling by DIJET QM MAX MQXTYPE ■ RECOMMENDED CUTTING CONDITIONS / UP & DOWN FINISHING ● MQX type (YPHW-15/-F type insert) + MSN Carbide Shank Holder Tool dia. (mm) 32/35 40/42 40 Work InsertMaterialsGradesNo. of teeth 6N No. of teeth 6N No. of teeth 7N ℓ Pf ae n Vf ℓ Pf ae n Vf ℓ Pf ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) Carbon steelS50C, S55C(C50, C55)~1000.8 <0.2 4,480 4,830 ~100 0.88 <0.2 3,580 3,870 ~100 0.88 <0.2 3,580 4,520JC8015(DH102)1500.8<0.24,4804,8301500.88<0.23,580 3,8701500.88<0.23,580 4,520 Below 250HB 210 0.8 <0.2 3,480 3,130 210 0.88 <0.2 2,790 2,010 210 0.88 <0.2 2,790 2,350 Die steelSKD61, SKD11(1.2344, 1.2379)Below 255HB~100JC8015(DH102)1502100.80.80.8<0.23,9804,300~1000.88<0.23,180 3,430 ~100 0.88 <0.2 3,180 4,000<0.23,9804,3001500.88<0.23,180 3,4301500.88<0.23,180 4,000<0.22,9802,0902100.88<0.22,390 1,7202100.88<0.22,390 2,010 Mold steelHPM7, PX5, P20(1.2311, P20)~100JC8015(DH102)1500.80.8<0.23,4803,130 ~100 0.88 <0.2 2,790 2,510 ~100 0.88 <0.2 2,790 2,930<0.23,4803,1301500.88<0.22,790 2,5101500.88<0.22,790 2,930 30-36HRC 210 0.8 <0.2 2,490 1,500 210 0.88 <0.2 1,990 1,430 210 0.88 <0.2 1,990 1,670 Mold steelNAK80, HPM1, P21JC8015(1.2311, P21)38-43HRC(DH102)~1001502100.80.80.8<0.22,4901,800~1000.88<0.2<0.22,4901,8001500.88<0.2<0.21,7808602100.88<0.21,990 1,430~1000.88<0.21,990 1,4301500.88<0.21,4208202100.88<0.21,990 1,6701,990 1,6701,420960 Hardened die steelSKD61, DAC, DHA(1.2344,1.2379)DH102(JC8015)~1001500.8<0.151,6901,020 ~100 0.88 <0.15 1,3500.8<0.151,6901,0201500.88<0.151,350810~1000.88<0.151,3508101500.88<0.151,350950950 42-52HRC 210 0.8 <0.15 1,210 490 210 0.88 <0.15 960 460 210 0.88 <0.15 960 540 Grey & Nodular ~100 0.8 <0.2 5,470 6,560 ~100 0.88 <0.2 4,380 5,260 ~100 0.88 <0.2 4,380 6,140 cast ironFC, FCD(GG, GGG)Below 300HBJC80151500.8<0.24,4806,560 150 0.88 <0.2 4,380 5,260 150 0.88 <0.2 4,380 6,140(DH102)2100.8<0.24,4804,0302100.88<0.23,580 3,2202100.88<0.23,580 3,760 ℓ: Overhung length, Pf : Pick feed, ae : Radial depth of cut, n : Spindle speed, Vf : Feed speed ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. B050 4) Use air blow to flush the chips out.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском