Общий каталог Dijet 2018 - страница 56

Навигация

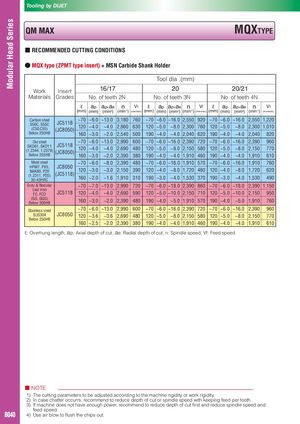

Modular Head Series Tooling by DIJET QM MAX MQXTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MQX type (ZPMT type insert) + MSN Carbide Shank Holder Tool dia .(mm) Work Insert 16/17 20 20/21 Materials Grades No. of teeth 2N No. of teeth 3N No. of teeth 4N ℓ ap ap×ae n Vf ℓ ap ap×ae n Vf ℓ ap ap×ae n Vf (mm) (mm) (mm2) (min-1) (mm/min) (mm) (mm) (mm2) (min-1) (mm/min) (mm) (mm) (mm2) (min-1) (mm/min) Carbon steelS50C, S55C(C50,C55)JC5118~70~6.0~13.03,180 760(JC8050)120~4.0~4.02,860630 ~70 ~6.0 ~16.0 2,550 920 ~70 ~6.0 ~16.0 2,550 1,220120~5.0~8.02,300760120~5.0~8.02,3001,010 Below 250HB 160 ~3.0 ~2.0 2,540 500 190 ~4.0 ~4.0 2,040 620 190 ~4.0 ~4.0 2,040 820 Die steel ~70 ~6.0 ~13.0 2,990 600 ~70 ~6.0 ~16.0 2,390 720 ~70 ~6.0 ~16.0 2,390 960 SKD61, SKD11 JC5118(1.2344, 1.2379)Below 255HB(JC8050)120160~4.0~3.0~4.02,690480~2.02,390380120 ~5.0 ~8.0 2,150 580 120 ~5.0190~4.0~4.01,910460190~4.0~8.02,150~4.01,910770610 Mold steel ~70 ~6.0 ~8.0 2,390 480 ~70 ~6.0 ~16.0 1,910 570 ~70 ~6.0 ~16.0 1,910 760 HPM7, PX5,NAK80, P20(1.2311, P20)30-43HRCJC8050(JC5118)120~3.0160~2.0~3.02,150390~1.61,910310 120 ~4.0 ~8.0 1,720 460 120 ~4.0190~3.0~4.01,530370190~3.0~8.01,720~4.01,530620490 Grey & Nodular ~70 ~7.0 ~13.0 2,990 720 ~70 ~6.0 ~18.0 2,390 860 ~70 ~6.0 ~18.0 2,390 1,150 cast ironFC, FCDJC5118 120 ~4.0 ~4.0 2,690 590 120 ~5.0 ~10.0 2,150 710 120 ~5.0 ~10.0 2,150 950 (GG, GGG)Below 300HB 160 ~3.0 ~2.0 2,390 480 190 ~4.0 ~5.0 1,910 570 190 ~4.0 ~5.0 1,910 760 Stainless steel ~70 ~6.0 ~13.0 2,990 600 ~70 ~6.0 ~16.0 2,390 720 ~70 ~6.0 ~16.0 2,390 960 SUS304 JC8050 120 ~3.6 ~3.6 2,690 480 120 ~5.0 ~8.0 2,150 580 120 ~5.0 ~8.0 2,150 770 Below 250HB 160 ~2.5 ~2.0 2,390 380 190 ~4.0 ~4.0 1,910 460 190 ~4.0 ~4.0 1,910 610 ℓ: Overhung length, ap: Axial depth of cut, ae: Radial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or spindle speed with keeping feed per tooth. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. B040 4) Use air blow to flush the chips out.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском