Общий каталог Dijet 2018 - страница 45

Навигация

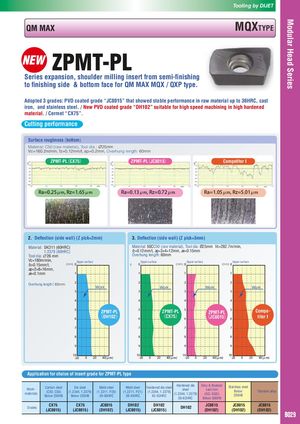

Modular Head Series Tooling by DIJET QM MAX MQXTYPE ZPMT-PL Series expansion, shoulder milling insert from semi-finishing to finishing side & bottom face for QM MAX MQX / QXP type. Adopted 3 grades: PVD coated grade “JC8015” that showed stable performance in raw material up to 36HRC, cast iron, and stainless steel. / New PVD coated grade “DH102” suitable for high speed machining in high hardened material. / Cermet “CX75”. Cutting performance Surface roughness (bottom) Material: C50 (raw material), Tool dia.: Ø25mm Vc=160.2m/min, fz=0.12mm/t, ap=0.2mm, Overhung length: 60mm ZPMT-PL(CX75) ZPMT-PL(JC8015) Competitor I Ra=0.25μm, Rz=1.65μm Ra=0.13μm, Rz=0.72μm Ra=1.05μm, Rz=5.01μm 2. Deflection (side wall) (Z pick=2mm) 3. Deflection (side wall) (Z pick=3mm) Material: SKD11 (60HRC) Material: 50CC50 (raw material), Tool dia: Ø25mm Vc=282.7m/min, 1.2379 (60HRC) fz=0.12mm/t, ap=3×4=12mm, ae=0.15mm Tool dia: Ø 26 mm Overhung length: 60mm Vc=180m/min, Upper surface Upper surface Upper surface Upper surface fz=0.15mm/t, (mm) 0 ç 0 (mm) 0 (mm) 0 ap=2×8=16mm, ae=0.1mm 1 1 1 1 Overhung length:65mm 2 Work 2 2 2WorkWork Work 3 3 3 3 4 4 4 4 5 ZPMT-PL 5 ZPMT-PL 5 ZPMT-PL 5 Compe- 6 (DH102) 6 (CX75) 6 (JC8015) 6 titor I 7 7 7 7 8 8 8 8 9 9 9 9 10 10 10 10 -20 0 20 40(μm) -20 0 20 40(μm) -20 0 20 40(μm) -20 0 20 40(μm) Application for choice of insert grade for ZPMT-PL type Work-materialsCarbon steel Die steel Mold steel(C50, C55)(1.2344, 1.2379)(1.2311, P20)Below 250HBBelow 255HB30-36HRCMold steel(1.2311, P21)38-43HRCHardened die steel(1.2344, 1.2379)42-52HRCHardened diesteel(1.2344, 1.2379)55-62HRCGrey & Nodularcast iron(GG, GGG)Below 300HBStainless steelBelow250HBTitanium alloy Grades CX75(JC8015) CX75 JC8015(JC8015)(DH102)DH102 DH102(JC8015)(JC8015)DH102 JC8015(DH102) JC8015 JC8015(DH102)(DH102) B029

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском