Каталог Carmex общий 2021 - страница 97

Навигация

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut

Каталог Carmex резьбофрезы из твёрдого сплава для обработки закалённых материалов HardCut Каталог Carmex корпуса резьбофрез для призматических пластин

Каталог Carmex корпуса резьбофрез для призматических пластин Каталог Carmex инструмент для вихревого нарезания резьбы

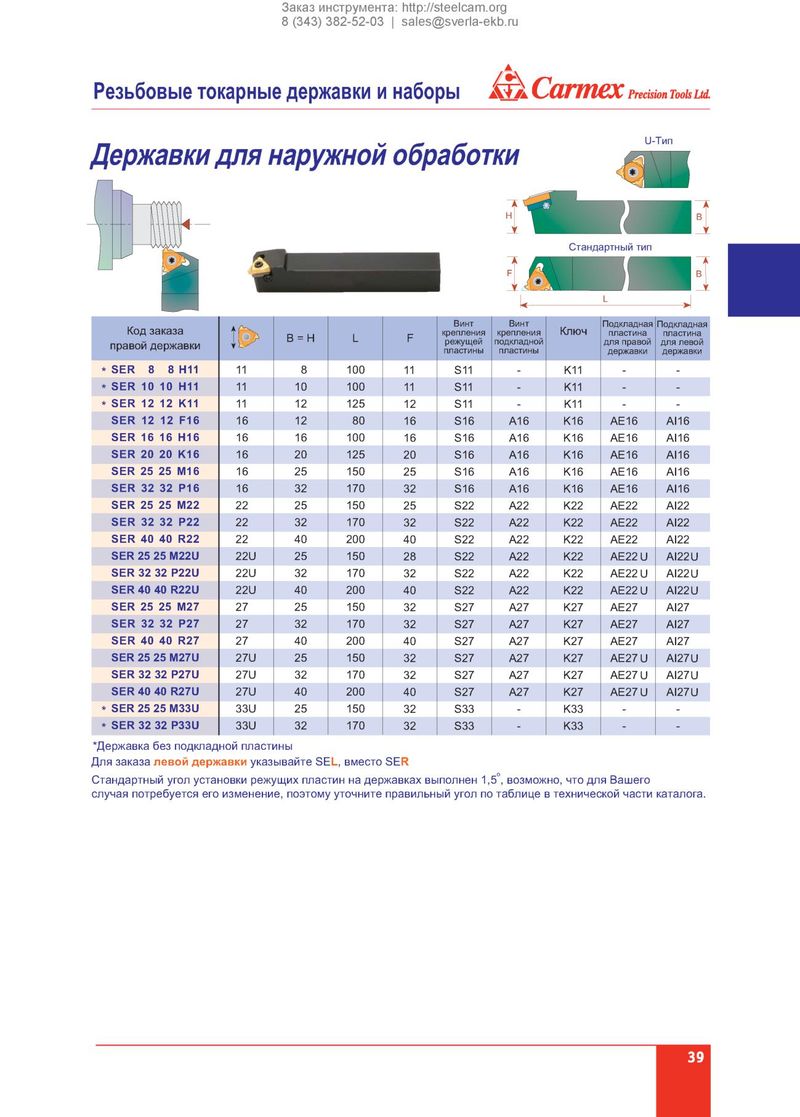

Каталог Carmex инструмент для вихревого нарезания резьбы Каталог Carmex державки для наружной обработки

Каталог Carmex державки для наружной обработки Каталог Carmex спиральные резьбофрезы со сменными пластинами

Каталог Carmex спиральные резьбофрезы со сменными пластинами

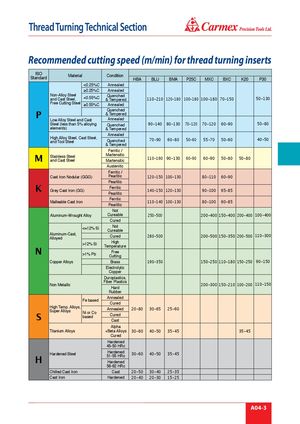

® Thread Turning Technical Section Recommended cutting speed (m/min) for thread turning inserts ISOStandard Material Condition HBA BLU BMA P25C MXC BXC K20 P30 <0.25%C Annealed ≥0.25%C Annealed Non-Alloy Steeland Cast Steel,<0.55%CFree Cutting Steel≥0.55%CQuenched& TemperedAnnealed110-210120-180100-180100-18070-15050-130 P Low Alloy Steel and Cast Quenched& TemperedAnnealed Steel (less than 5% alloyingelements)Quenched& Tempered 90-140 80-130 70-120 70-120 60-90 50-80 High Alloy Steel, Cast Steel,and Tool SteelAnnealedQuenched& Tempered70-9060-8050-60 55-70 50-60 40-50 Ferritic / M Stainless Steeland Cast Steel MartensiticMartensitic 110-160 90-130 60-90 60-90 50-80 50-80 Austenitic Ferritic / Cast Iron Nodular (GGG) Pearlitic 120-150 100-130 80-110 60-90 Pearlitic K Grey Cast Iron (GG) FerriticPearlitic 140-150 120-130 90-100 65-85 Malleable Cast Iron FerriticPearlitic 110-140 100-130 80-100 60-85 Not Aluminum-Wrought Alloy Cureable 250-500 200-400 150-400 200-400 100-400 Cured <=12% Si NotCureable Aluminum-Cast,Alloyed Cured 280-500 200-500 150-350 200-500 110-300 N >12% Si HighTemperature>1% PbFreeCutting Copper Alloys Brass 190-350 150-250 110-180 150-250 90-150 Electrolytic Copper Duroplastics, Non Metallic Fiber PlasticsHard 200-300 150-210 100-200 110-150 Rubber Fe based AnnealedCured High Temp. Alloys,Super AlloysSNi or CobasedAnnealed20-8030-65 25-60CuredCast Alpha Titanium Alloys +Beta Alloys 30-60 40-50 35-45 35-45 Cured Hardened 45-50 HRc Hardened SteelH Hardened51-55 HRc30-60 40-50 35-45Hardened 56-62 HRc Chilled Cast Iron Cast 20-50 30-40 25-35 Cast Iron Hardened 20-40 20-30 15-25 A04-3