Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы - страница 182

Навигация

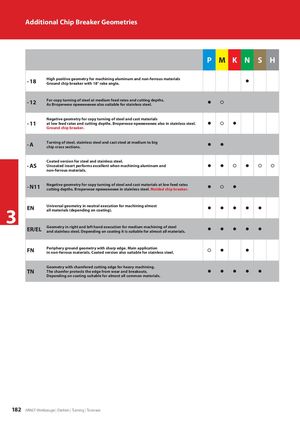

Additional Chip Breaker Geometries P M K N S H - 18 High positive geometry for machining aluminum and non-ferrous materialsGround chip breaker with 18° rake angle.z - 12 For copy turning of steel at medium feed rates and cutting depths.As Вторичное применение also suitable for stainless steel.z Negative geometry for copy turning of steel and cast materials - 11 at low feed rates and cutting depths. Вторичное применение also in stainless steel. z z Ground chip breaker. -A Turning of steel, stainless steel and cast steel at medium to bigchip cross sections. z z Coated version for steel and stainless steel. - AS Uncoated insert performs excellent when machining aluminum and z z z non-ferrous materials. - N11 Negative geometry for copy turning of steel and cast materials at low feed ratescutting depths. Вторичное применение in stainless steel. Molded chip breaker.zz 3 EN Universal geometry in neutral execution for machining almostall materials (depending on coating).zz z z z ER/EL Geometry in right and left hand execution for medium machining of steeland stainless steel. Depending on coating it is suitable for almost all materials.zzzzz FN Periphery ground geometry with sharp edge. Main applicationin non-ferrous materials. Coated version also suitable for stainless steel.zz Geometry with chamfered cutting edge for heavy machining. TN The chamfer protects the edge from wear and breakouts. z z z z z Depending on coating suitable for almost all common materials. 182 ARNO®-Werkzeuge | Drehen | Turning | Точение

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015 Каталог ARNO инструмент для обработки отверстий 2016

Каталог ARNO инструмент для обработки отверстий 2016 Каталог ARNO монолитный осевой инструмент

Каталог ARNO монолитный осевой инструмент Каталог ARNO оснастка для автоматов продольного точения

Каталог ARNO оснастка для автоматов продольного точения Каталог ARNO тиски станочные

Каталог ARNO тиски станочные Каталог ARNO концевые твердосплавные фрезы AFV

Каталог ARNO концевые твердосплавные фрезы AFV