Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы - страница 159

Навигация

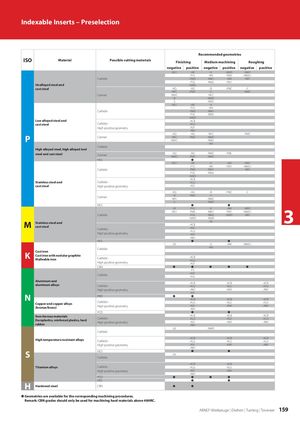

Indexable Inserts – Preselection Recommended geometries ISO Material Possible cutting materials Finishing Medium machining Roughing negative positive negative positive negative positive -NS1 -AB -K -WMS -NM1 -PF2 -NA -PMS -NMG1 Carbide -PMS -NM1 -AM -NR1 -PS2 -NM2 -PM1 Unalloyed steel and -WMS cast steel -AQ -AQ -B -PMC -C -NFC -PMC -C -NMC Cermet -NWC -NFC -B -NMC -S -NWC -NS1 -AB -K -PF2 -NA Carbide -PMS -NM1 -PS2 -NM2 -WMS Low alloyed steel and -ACB cast steel Carbide - -ALU High positive geometry -ASF -AWI -AQ -AQ -NFC -PMC P Cermet -NFC -PMC -NMC-NWC-NWC -NA Carbide High alloyed steel, high alloyed tool steel and cast steel Cermet -AQ -AQ -NMC -PMC-NWC-PMC-NWC HSS Ê -NS1 -AB -K -AM -NM1 -PF2 -NA -PM1 -NMG1 Carbide -PMS -NM1 -NR1 -PS2 -NM2 -WMS -ACB Stainless steel and Carbide - -ALU cast steel High positive geometry -ASF -AQ -AQ -B -PMC -C Cermet -B -PMC -C-NFC-NMC -S -NWC HSS Ê Ê -EX -PF2 -K -AM -NM1 CarbideMStainless steel andcast steelCarbide - -NS1 -PMS -NM1 -PM1 -NMG1-PS2-NM2-WMS-NR1-WMS-NMR-VA3-ACB-AEC -ALU High positive geometry -ASF -AWI HSS Ê Ê -EX -K -AM -NMG1 Carbide -NA Cast iron K Cast iron with nodular graphiteMalleable iron Carbide - -ACB-ALU High positive geometry -ASF CBN Ê Ê Ê Ê Ê -PS Carbide -AEC-PF2 Aluminum andaluminum alloys Carbide - -ACB -ACB -ACB-ALU-ALU-ALU High positive geometry -AWI -AWI -AWI -ASF N PKD Ê Ê-ACB -ACB -ACB Copper and copper alloys Carbide -(bronze/brass)High positive geometry -ALU -ALU -ALU-ASF-AWI-AWI-AWI PCD Ê Ê Non-ferrous materials Carbide -Duroplastics, reinforced plastics, hardrubberHigh positive geometry-ACB -ACB -ACB-ALU-ALU-ALU-ASF-AWI-AWI-AWI -EX -NMR Carbide High temperature resistant alloys Carbide - -ACB -ACB -ACB-ALU-ALU-ALU High positive geometry -ASF -AWI -AWI -AWI S HSS Ê Ê-EXCarbide -ACB -ACB Titanium alloys Carbide - -ALU -ALU High positive geometry -ASF -AWI -AWI PCD Ê Ê Ê Ê HSS Ê Ê H Hardened steel CBN Ê Ê Ê Geometries are available for the corresponding machining procedures. Remark: CBN grades should only be used for machining hard materials above 48HRC. ARNO®-Werkzeuge | Drehen | Turning | Точение 159

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015 Каталог ARNO инструмент для обработки отверстий 2016

Каталог ARNO инструмент для обработки отверстий 2016 Каталог ARNO монолитный осевой инструмент

Каталог ARNO монолитный осевой инструмент Каталог ARNO оснастка для автоматов продольного точения

Каталог ARNO оснастка для автоматов продольного точения Каталог ARNO тиски станочные

Каталог ARNO тиски станочные Каталог ARNO концевые твердосплавные фрезы AFV

Каталог ARNO концевые твердосплавные фрезы AFV