Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы - страница 15

Навигация

ARNO TODAY 0 Strength from experience, competence and development. “For the future you need a partner with future.” By working closely with partners inside and outside the company, we are very capable of satisfy- ing individual requirements which often lead to special tooling. These tools are consistently im- proved and might find their way into our standard portfolio of catalogue tooling later. New materials and expectations of constant improvement of machine time, motivate us to re- search and develop new tooling and cutting tool materials. That means developing modular tooling systems that are modified for each indvidual application. Our high performance but still affordable solu- tions include our extensive range of drilling systems, grooving systems, milling cutters and our huge range of indexable inserts (not just for turning) as well as tool holding and vending solutions. Our technical support and advice follow any of our high quality tools. Our highly competent team will support you with service even after you have made your decision to purchase. Milling Tool Vending Work Holding Equipment Face-mills, square shoulder-mills, chamfer-mills, mill- Secure storage, monitoring and usage reporting NC-machine vice in various executions of ing cutters with round inserts, roughing guaranteed with our highly flexible StoreManager number of jaws and widths ensure maximum cutters and solid carbide cutters. We have the right solution. component clamping for the modern manu- cutter for your application. facturing. ARNO®-Werkzeuge | Drehen | Turning | Точение 15

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015 Каталог ARNO инструмент для обработки отверстий 2016

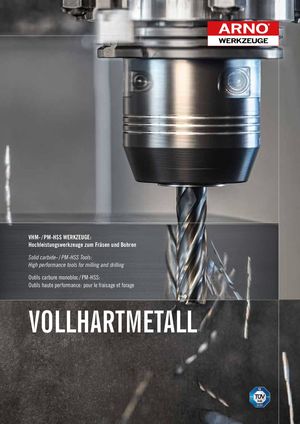

Каталог ARNO инструмент для обработки отверстий 2016 Каталог ARNO монолитный осевой инструмент

Каталог ARNO монолитный осевой инструмент Каталог ARNO оснастка для автоматов продольного точения

Каталог ARNO оснастка для автоматов продольного точения Каталог ARNO тиски станочные

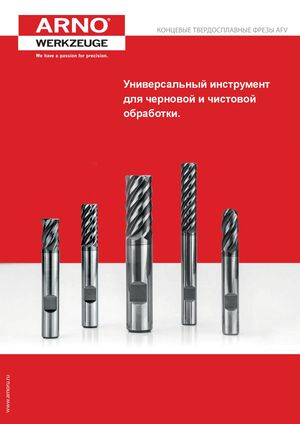

Каталог ARNO тиски станочные Каталог ARNO концевые твердосплавные фрезы AFV

Каталог ARNO концевые твердосплавные фрезы AFV